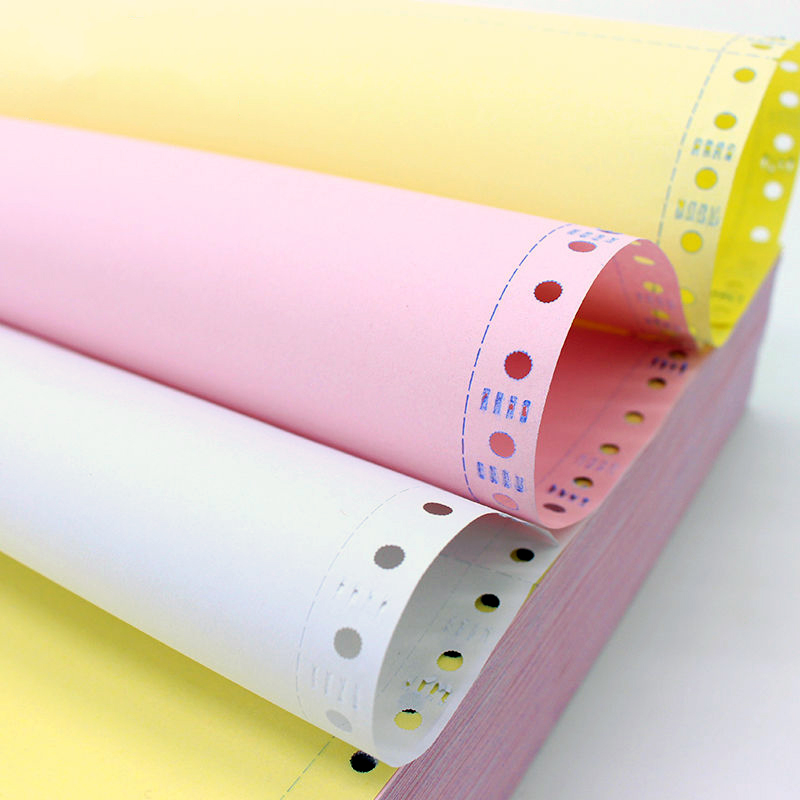

Carbonless copy paper is divided into upper paper, middle paper and lower paper. Carbonless copy paper is widely used for its convenience, simplicity, and cleanliness. The appearance, color rendering effect, inking performance, and surface strength of carbonless copy paper will all affect the use effect of carbonless copy paper. In addition to the original white and high white, the appearance of carbonless copy paper also has colors such as yellow, blue, red and green. Although the appearance of colored carbonless copy paper is beautiful, it is easy to cause some quality problems, such as white spots on the paper.

The white spot quality problem of carbonless copy paper mainly occurs on the CF side of the paper. There are many factors that cause white spots on the CF side. Generally speaking, there are the following aspects:

Poor quality of dispersant will lead to poor pigment dispersion effect in paint; when the amount of dispersant is small, the pigment particles not wrapped by dispersant will flocculate and precipitate due to electrical attraction; when the amount of dispersant is too large, excessive dispersant will Destroy the electric double layer formed by the pigment, causing the unbalanced distribution of charges and resulting in precipitation. When the coating is applied on the machine, the flocculated pigment particles cannot be coated and cause white spots on the paper. The optimal amount of dispersant can be determined through experimental analysis, and generally the amount of dispersant added is about 0.5%-2.5% of the pigment.

The pH value has a decisive effect on the dispersion (stability) of carbonless paper pigments. When the pigment is dispersed, alkali can be added to adjust the pH to be alkaline, preferably between 7.5 and 8.5.

Defoamers eliminate air bubbles in paint. However, the defoamer is generally an organic substance that is difficult to dissolve in water. Excessive use or improper addition method will cause the defoamer to form a “cloud point” on the paper, which will cause the CF coating to fail to apply and form white spots. This problem can be solved by properly diluting and spraying on the surface of the paint with air bubbles.

CF coatings have a lot of air bubbles, and when the coating is applied, the bubbles burst on the paper, causing white spots. This is also the main reason why carbonless copy paper causes white spot paper disease. The solution is to add a foam inhibitor to prevent the generation of bubbles when the pigment is dispersed, or add a defoamer to eliminate the bubbles that have already occurred.

Other auxiliary materials (especially organic auxiliary materials) added to CF coatings, if the quality of the lubricant is not good, it will cause poor dispersion and stick to the paper, resulting in the failure of CF coatings to form white spots. So use good quality chemical auxiliary materials as much as possible.

Post time: Dec-05-2022