The one-side coated white board is a kind of paper with a white and smooth front and gray back. It is also known as (coated) duplex board with a gray back. After single-sided color printing, this cardboard is mainly used for packaging. The normal sheet size of the coated white board is 787mm * 1092mm, 889mm * 1194mm, and the width of the roll is 787 mm, 889mm, 1092mm, 1194mm. Other sizes can also be produced according to customers needs.

With uniform fiber organization, the surface layer of the coated white board has the ingredients of filler and glue. After multiple roller pressing treatments and coating, the texture of the cardboard is tight. Thanks to even thickness and sink absorption, the paper is generally white and smooth. It also has little surface powder and hair. With good folding resistance and around 8% water content, there is certain scalability, which has an impact on printing.

The difference between white board art paper, offset paper and convex plate paper lies in basis weight. The former is usually thicker and heavier. The pulp of white paper is generally divided into pulp (surface layer), two, three, and four layers. The fiber ratio in each layer is different, which affects the quality of the paper. The first layer is a surface layer slurry, which demands high whiteness and a certain degree of strength. It’s usually made of bleached sulfate wood pulp or with partial bleached chemical grass pulp and waste pulp from the edge of white paper; The second layer is the lining layer, the isolation surface layer, and core layer, also requires a certain whiteness, which is usually made from 100% mechanical wood pulp or light color waste pulp; the third layer is the core layer, a filling role, to increase the thickness of the cardboard and strengthen stiffness, which is the thickest layer and generally made from mixed waste pulp or pulp. The fourth layer is the bottom layer with the function of embellishing appearance, improving strength, and preventing from being curling. It is usually made from the good waste pulp as raw material. Most back of this white board is gray, but it can be other colors as required.

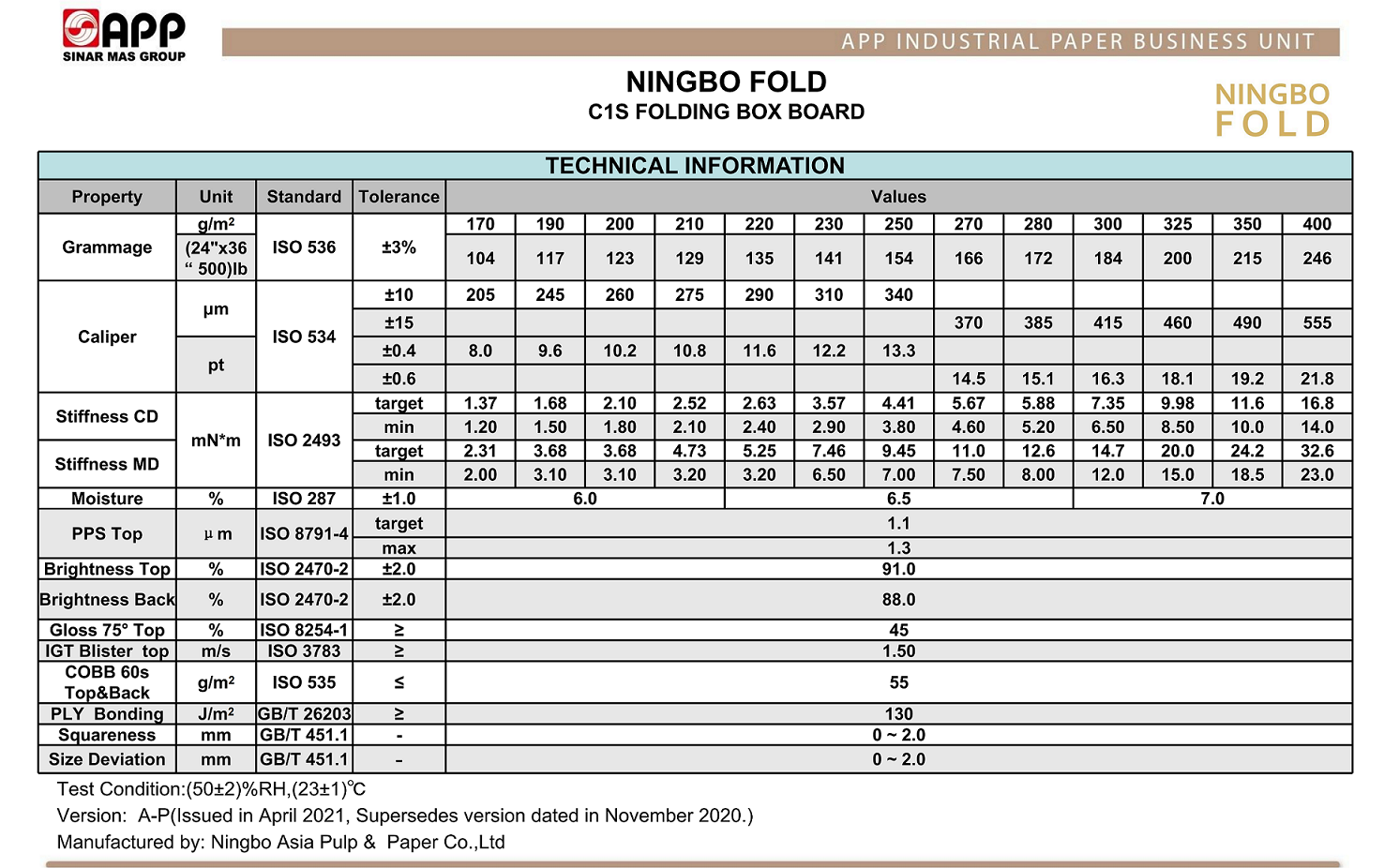

Ivory board is mainly used for printing business cards, covers of books, certificates, invitation cards, and packages. Its main size is 880mm * 1230mm, 787mm * 1032mm. According to whiteness, it can be divided into levels A, B and C with at least 92.0%、87.0%、82.0% respectively. Ivory board is thick and strong with various specifications including 200gsm, 220gsm, 250gsm, 270gsm, 300 gsm, and 400gsm. The tightness of this kind of paper is usually not less than 0.80 g/m3 and demands high whiteness. In order to prevent being smudged, the ivory board requires a large degree of glue with no less than 1.5mm, 1.5mm, and 1.0mm respectively. In order to keep paper even, the white paper should be thick and strong, with high stiffness and bursting strength. For different basis weights, the higher the grade and weight are, the greater the stiffness is. Generally, machine stiffness should not be less than 2.10-10.6mNm, and the cross stiffness should not be less than 1.06-5.30mNm.

The bursting index of A, B, C is not less than 2.00 Kpa, 1.60 Kpa, and 1.20 KPa respectively. In order to ensure the uniform distribution of ink during the printing, the smoothness of FBB is not less than 20-40S. In addition, the paper surface of the ivory board should be flat. Paper defects such as spots, streaks, and warping deformation are not allowed. No dust larger than 1.5mm2 is allowed. FBB is usually made from 100% bleached wood pulp as raw material, whose surface layer and bottom layer are made from sulfate chemical softwood pulp. The core layer is made from hardwood chemical mechanical pulp. AKD carries out neutral and heavy sizing. It is made on a laminating paper machine then it needs to be calendered and coated. According to needs, after embossing, it can produce cardboard with special embossing patterns. For white cardboard with a special embossed pattern, smoothness and whiteness can not be tested out. In addition to whiteness, by dyeing the pulp, various colors can also be produced on it. At this time, except for whiteness, other technical properties are consistent with those of white cardboard.

Post time: Feb-25-2022