PE COATED BOARD

Food grade paper board is commonly and wildly used in our daily life. It can be individually molded into a paper cup or a food box but in most cases it needs to be processed first—Coating (Laminating) can make it achieve a better function performance.

PE coating(Lamination) can improve the waterproof, abrasion, heat and pollution resistance of the coated paper, as well as improve the gloss and touch of the coated paper, and enhance the durability and folding resistance of the coated paper.

The technology is widely used in various fields. Printed materials, color box packaging, book covers and other fields, such as high-grade color printing albums, business cards, advertising leaflets and other printed materials, gift boxes, wine boxes, cosmetic boxes and other color box packaging, book covers, book jackets, album covers and other fields.

Ordinary paper is composed of wood fibers, which is very absorbent and does not perform well in high humidity environments. PE coated paper has hot-melted PE evenly to the surface by using a laminating machine to form a film. So it can prevent water immersion and has better waterproof performance and leakage performance, no leakage, oil, acid resistance, better protection of cups / bowls of food inside not to leakage, outside the dip situation. Due to its waterproof and oil-proof, it is mainly used for food cartons, paper cups, paper bowls and packaging, also can be used as industrial waterproof paper.

Depending on the usage, we can choose different paper base and coating(lamination) methods. Nowadays in Chinese market, the commonly used food grade paper is divided into two categories: Uncoated paper (PCM/ FK1/ FKO/ PCB/ FNO/ FCO) and Coated paper (GCU/ PCC/ PCB/ PCKB/ FVO).

Uncoated food grade paper base

Uncoated food grade paper has a uniform surface and good stiffness, without a fluorescent. Good adaptability to post-processing, satisfying various packaging processes such as coating(lamination), cup making and other processing techniques. Through the QS certification license, FSC / PEFC certification, the products are sent to the inspection every year, in line with the FDA21 Ⅲ and other European and American packaging directives, regulations and requirements.

PCM/ FK1/ FKO/ PCB are all cupstock paper, can be made into paper cups, hot drink cups and cold drink cups. With one side PE (hot cups), it can be used to hold hot water, tea, beverages, milk; With two side PE (cold cups), it can be used to hold cold beverages, ice cream,etc. The main difference is they have different gsm and bulk thickness, so you can choose the most suitable products according to your needs.

BOHUI - PCB+PE: special paper for paper cups

GSM: 210/230/240/280/300/310/320

PCB is also a base paper board without coating. It is specially for high-grade coffee paper cup processing.

Here the Chinese local famous brand - Luckin Coffee use this brand with over 1200,000 cups per month.It is enough to prove how good the quality of this paper is.

3.APP - FNO/FCO

FNO GSM: 210/240/340 (high bulk)

FCO GSM: 230/245/260/275 (high bulk)

If you have a need for bowl making, FNO/FCO is a great choice. FNO/FCO is the special paper for bowls. After coating with PE, it can be applied as fast food containers for rice, vegetables, soup and other foods.

BOHUI - Coated food grade paper

1.BOHUI - Allyking Cream/GCU+PE: Surface two layers blade coated

GSM: 215/220/235/240/250/270/295

GCU has super high bulk(1.63-1.73), it is ultra-lightweight and has high stiffness, good uniformity, smooth and delicate surface, exquisite printing effect, and excellent box-forming performance;

GCU is low-carbon and environmental friendly with lower paper cost. Due to it’s unique water-resistant formula, GCU can be used for frozen and chilled food (fresh, meat, ice cream, frozen food, etc.) and cold chain storage and transportation. In addition, it can also be used for solid food (popcorn, cake, etc.) packaging.

GCU Materials is approved by food certification, non-fluorescent; Passed FSC certification and complies with ROHS/REACH/FDA and other directives and regulations;

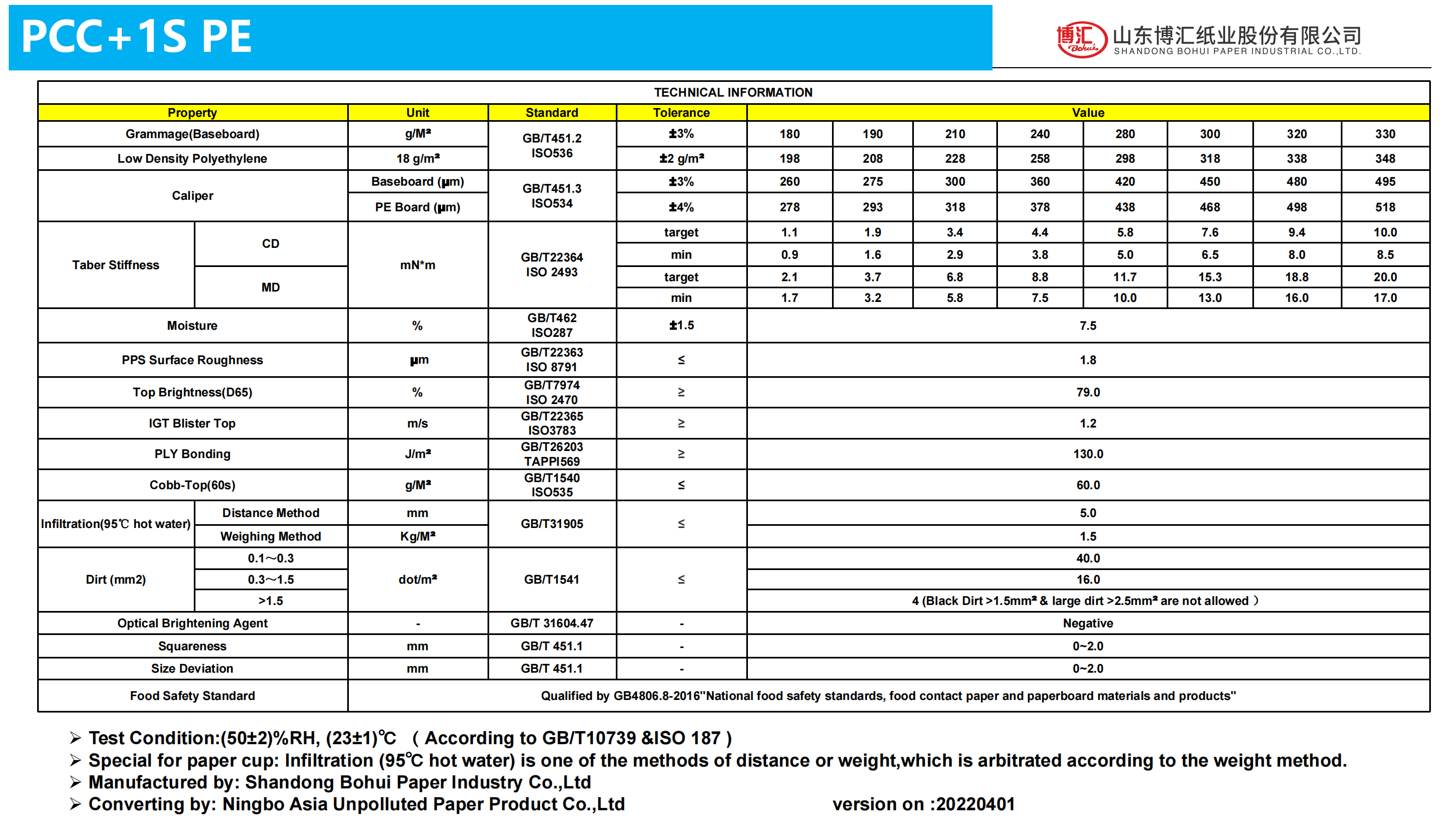

2.BOHUI - PCC+PE: Surface two layers blade coated

GSM: 180/190/210/240/260/280/300/320/330/350

Fine coating, low PPS, high paper smoothness. Uniform thickness, good surface flatness, excellent offset flexo printing suitability, uniform printing ink, high stiffness, high printing speed.

It has good post-processing adaptability, and the back side can meet processing techniques such as lamination(coating) and cup making;

Comply with QS food certification, non-fluorescent, FSC\PEFC certification, the product is sent to the annual inspection with GB4806 food-grade white card series of standards, ROHS\REACH\FDA21 Ⅲ and other European and American packaging directives, regulations and other compliance reports.

PCC can be laminated with single side or double side PE coating. With single side PE coating PCC can be used to make hot beverage cups to hold ready-to-eat drinking water, tea, drinks, milk, etc. With double side PE coating can be used to make cold beverage cups to hold cold drinks, ice cream, etc.

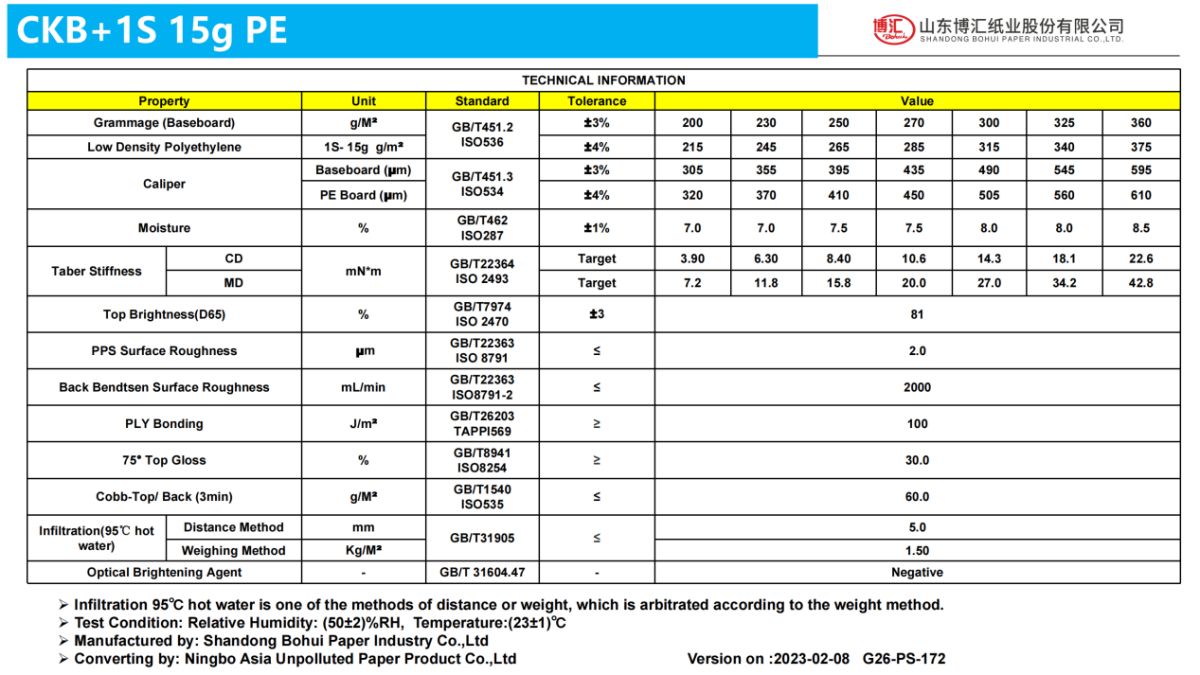

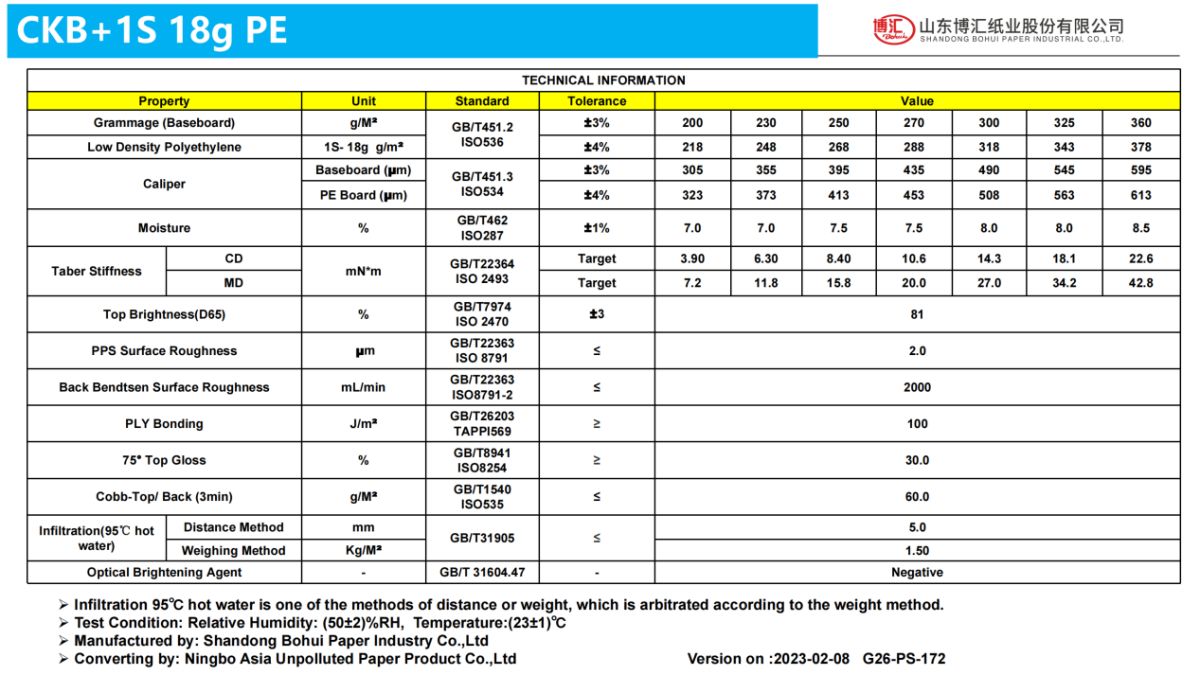

3.BOHUI - CKB+PE:

GSM: 200/230/250/270/300/325/360

CKB (Coated Kraft Back) is made of 100% pure virgin fiber from responsibly managed forests. It is food-safe packaging board that stands up to cold and wet environments;

With a kraft back for an eco-friendly impression and a smooth white surface for branding, CKB Carrier is the ideal choice for beer multipacks, food-safe packaging and other beverage, food and non-food packaging applications that require ultimate durability combined with excellent printing adaptability.

The strong virgin kraft fibers make CKB highly material efficient and light-weight perfect for today’s consumers who also pay attention to the packaging itself, not just to what’s inside it. And CKB could replace plastics in carrier multipacks which contributes to our environmental protection.

CKB with one side or two side PE coating is ideal packaging material for folding cartons for dry, chilled and frozen food, refrigerated food packaging, chocolate, wine and most other food folding carton applications.

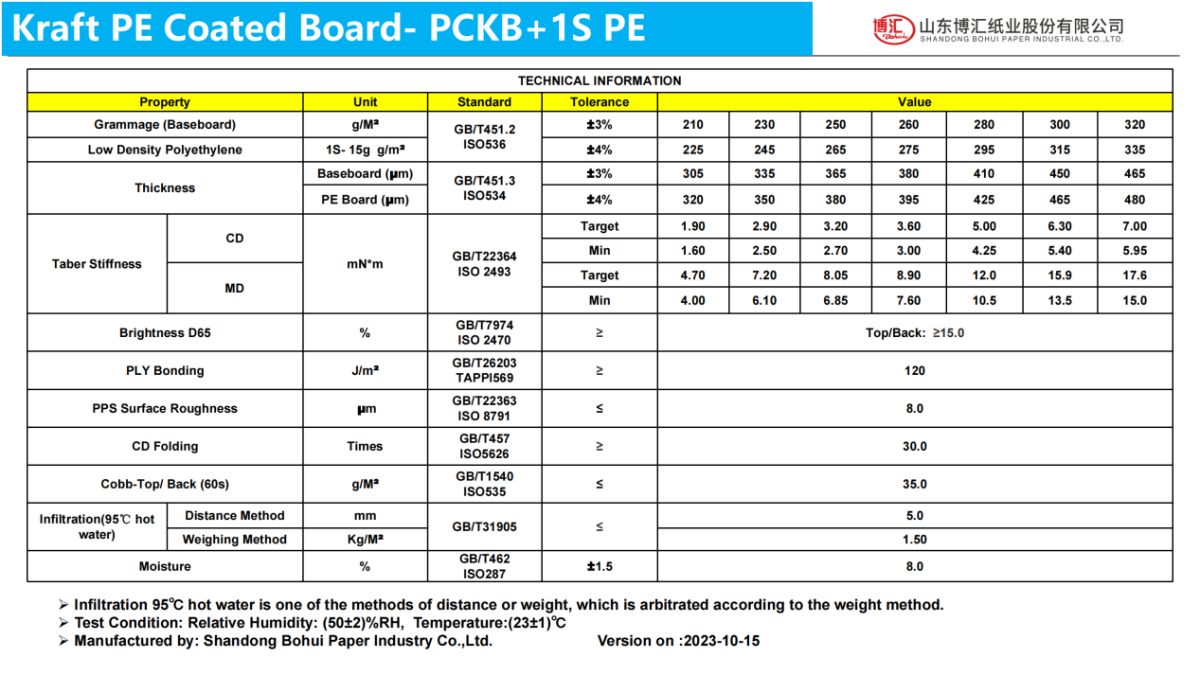

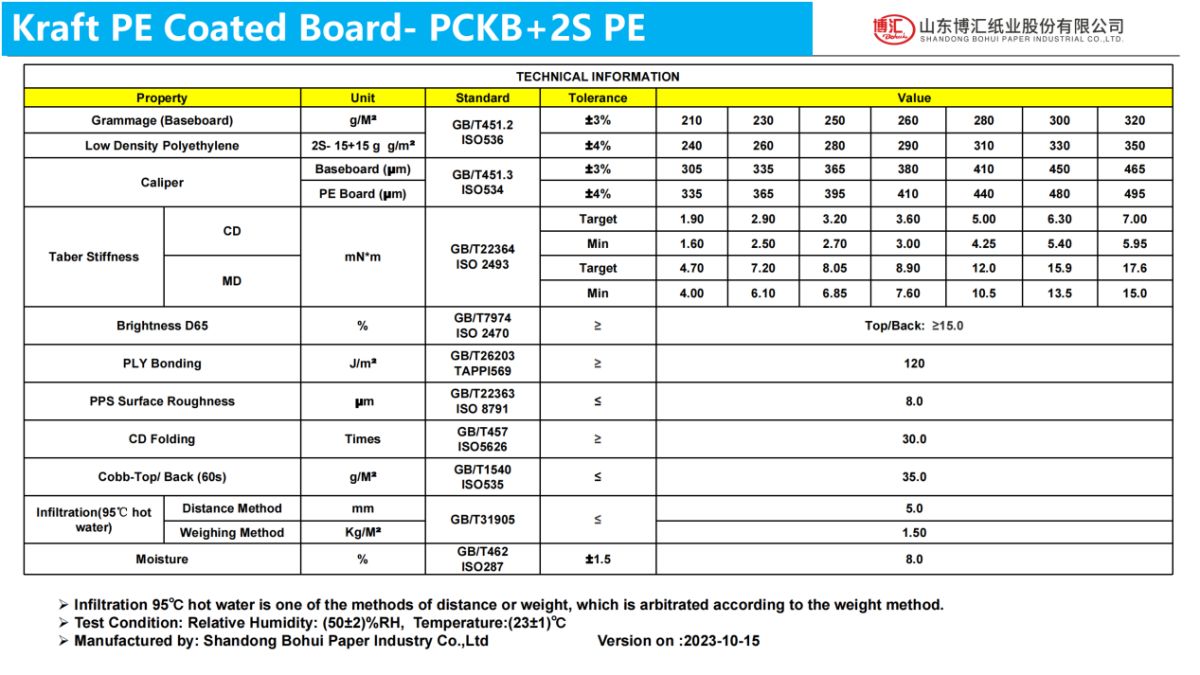

4.BOHUI - PCKB+PE:

GSM: 210/230/250/260/280/300/320

PCKB is a new launched paper product from BOHUI paper mill.

CKB is one side white and one side brown food grade Kraft board while PCKB is both side brown! The brown color of PCKB is the natural color of the high-quality, eco-friendly virgin fiber, it’s unbleached and manufacturing process also uses less water and resources than ivory board so it’s super-sustainable. Everything in this collection is plastic-free and 100% recyclable, home compostable and biodegradable.

PCKB can be applied as Kraft cupstock, and can be laminated with single side or double side polyethylene (PE). Double side PE provide a moisture barrier and enhance the cup’s rigidity and insulation properties. Kraft cupstock offers a sustainable alternative to traditional white cupstock, boasting a unique and eco-friendly appearance thanks to its natural color. Experience the same functionality with a more environmentally conscious appearance. PCKB can also be made into food containers like food bowls, food trays and so on.

APP - Coated food grade paper

1.APP - FVO+PE:

GSM: 215/235/250/275/295/325/365

FVO is lightweight, of high stiffness and good uniformity. Materials approved by food certification, non-fluorescent;

FVO is lightweight food packaging special paper, it is suitable for packaging boxes due to its smooth and delicate surface and exquisite printing effect.

It is QS certified, passed FSC certification and complies with ROHS/REACH/FDA and other directives and regulations;

FVO can be used to make facial tissue packaging, high-grade cosmetic packaging. Suitable for maternal and infant skin-friendly products, feminine products, personal hygiene products. Also suitable for solid food packaging products, such as popcorn buckets, cereal, cake boxes, and solid food Packaging: like milk powder, and so on.

FVO can replace social card/white board paper and so on. It can also reduce cost.

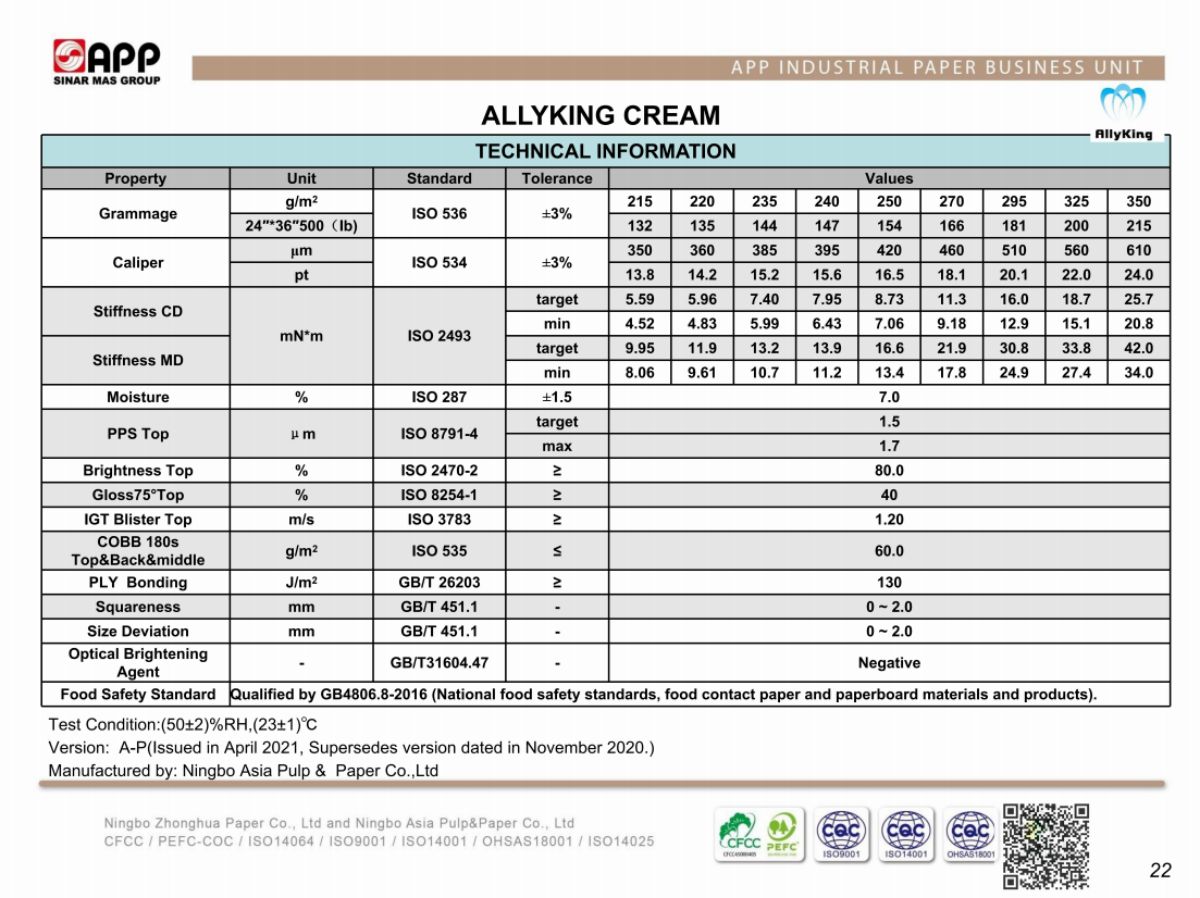

2.APP -Allyking Cream/ GCU+PE:

GSM: 215/220/235/240/250/270/295/325/350

APP GCU passed QS certification, and have passed the tests of many international standards such as the US and EU, and are in compliance with the food contact regulations and standards.

APP GCU is super high bulk product so it is ultra-lightweight, made entirely from wood pulp, without fluorescent whitening agents, has good stiffness and uniform thickness.

After post-processing, GCU is well formed and does not deform, and can be laminated on the back (please confirm the printing effect on the front before laminating). Unique water-resistant formula, suitable for solid food packaging, frozen and refrigerated product packaging. It is widely used in various types of packaging that are in direct contact with food and social packaging such as medicine boxes and daily necessities. It is ultra-lightweight and has the advantages of good printing, processing and molding performance.

As a ultra-lightweight food-grade ivory board, it provides the industry with environmentally friendly, safe and lightweight paper options and solutions. It can bring the ultra-light experience of packaging, use less raw materials to realize the same packaging texture needs, reduce the burden for life, and reduce the cost of paper.

Compared with other papers, it has good stiffness, giving the package a more excellent texture experience, flat and delicate surface with excellent paper strength, guaranteeing the product performance and printing effect of the package. Stiffer and stronger, making the package more high-grade.

Passed PEFC green forest certification from forest to paper. Strict supplier access mechanism and rigorous quality control mechanism for raw materials to ensure the traceability and quality of raw materials. And have passed the QS certification.

More Functional. Unique water-resistant formulas are incorporated to make paper packages easy to handle for cold chain storage and transportation, so that fresher food can be delivered to you conveniently and completely.

You may find APP/BOHUI both have the Allyking Cream/GCU , yes ,it is true .

Since BOHUI paper mill was acquired by APP Group, their machinery, equipment and teams have been slowly integrated, and the quality of paper produced by Bohui Paper has gradually improved to be comparable to that of APP. This is undoubtedly a good thing for consumers.

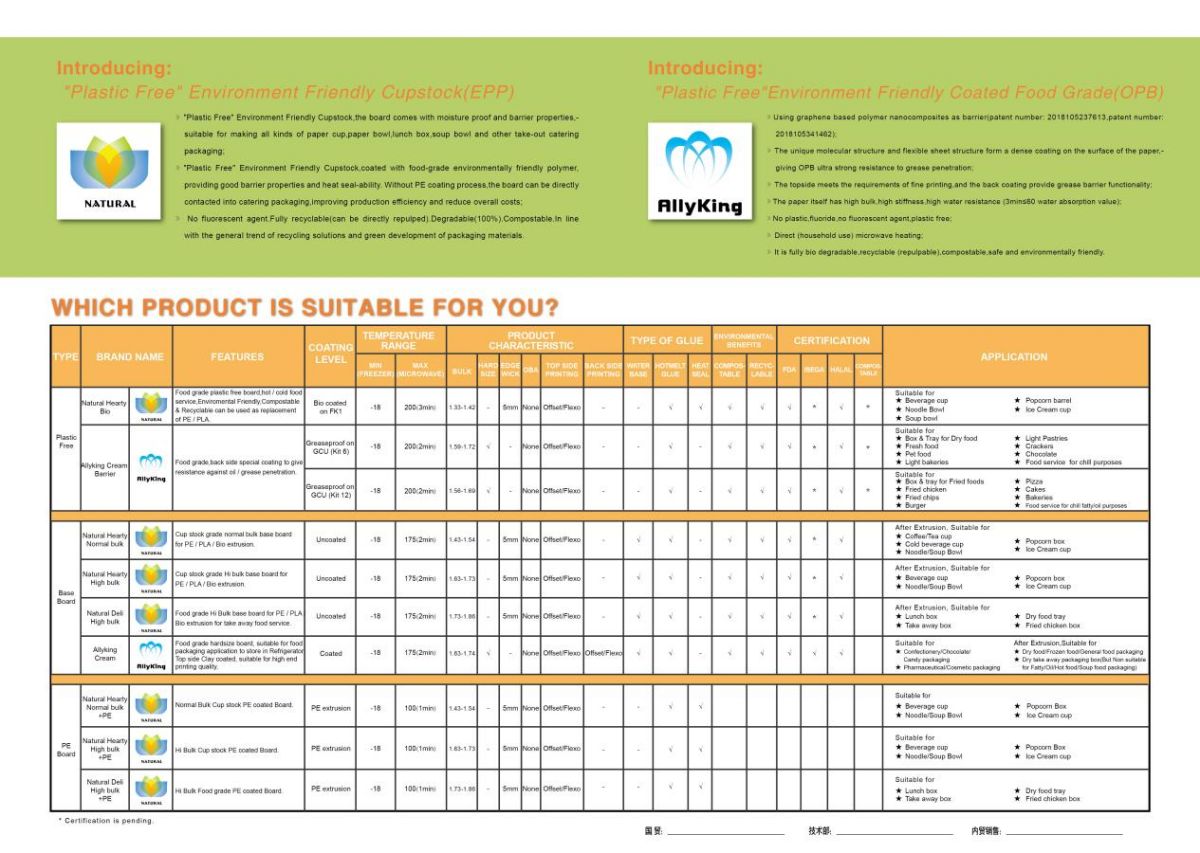

Plastic-free paper

Since plastics are such a prominent material around the world, bio-plastics were developed to combat the issues we face with conventional plastics. The most commonly used compostable bio-plastic is a clear bio-plastic material called polylactic acid (PLA). These products can look similar to traditional petroleum plastic and although they may look identical they are very different. The main difference is that PLA degrades faster when it is exposed to the right environmental conditions (composting) while conventional plastics can take decades to degrade.

PLA (Polylactic Acid) is a biodegradable material with excellent degradability. However, paper cups made of PLA lamination are only suitable for industrial degradation, and the degradation process causes more serious pollution to the environment.

PLA bioplastics are made from polylactic acid, a transparent thermoplastic aliphatic polyester made from renewable resources. Bio-based plastics like PLA are derived from biomasses like corn, sugarcane, seaweed, or even shrimp shells. PLA is also biodegradable, meaning it breaks down in natural environments and only leaves behind biomass, carbon dioxide, and water.

It’s important to note that not all bio-based plastics are necessarily biodegradable, and vice-versa. PLA bioplastics are the only commercially available bioplastics that are both bio-based and biodegradable, and they are one of the few bioplastics suitable for 3D printers.

Compared with the traditional polyethylene PE laminated paper, PLA laminated paper not only serves as waterproof, oil-proof, and heat-insulating, but also has the characteristics of non-toxic, fully compostable and biodegradable.

It is 100% bio-based, conforming to EN13432 and ASTM D6400. In composting environment, it completely decomposes into carbon dioxide and water, environmentally friendly, non-toxic, low carbon release, non-toxic and harmless to human body, organisms, and the environment, and safer to use.

As the global fever to protect the environment gradually strengthens, various industries will create a green recycling industry to realize high-quality sustainable development. In the context of the "carbon peak", "carbon neutral" era, more and more paper companies in the low-carbon environmental protection, green development focus on efforts.

In 2020, APP China officially launched the "Zero Plastic" paper cups and paper products. The product is completely free of plastic components, with recyclable, industrial explanation, compostable and other environmental characteristics, and also has good waterproof and impermeable performance, which can replace the traditional plastic coated paper cups. The coating can effectively block hot water, coffee, milk tea and other liquids, with good barrier properties, sealing resistance, printing effects, recyclability of water-based coating.

Our “Zero Plastic” main products are as follows

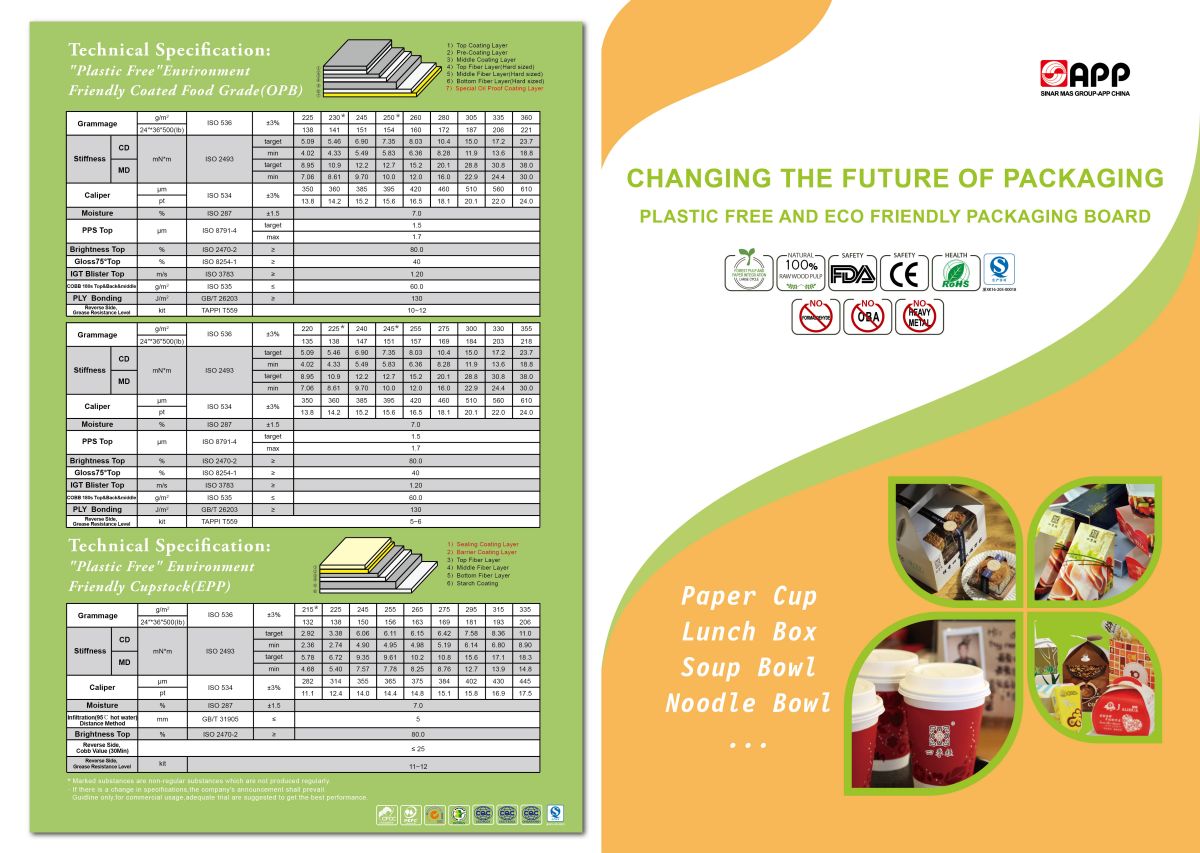

1.APP - OPB:

(paper base is APP-Allyking Cream GCU)

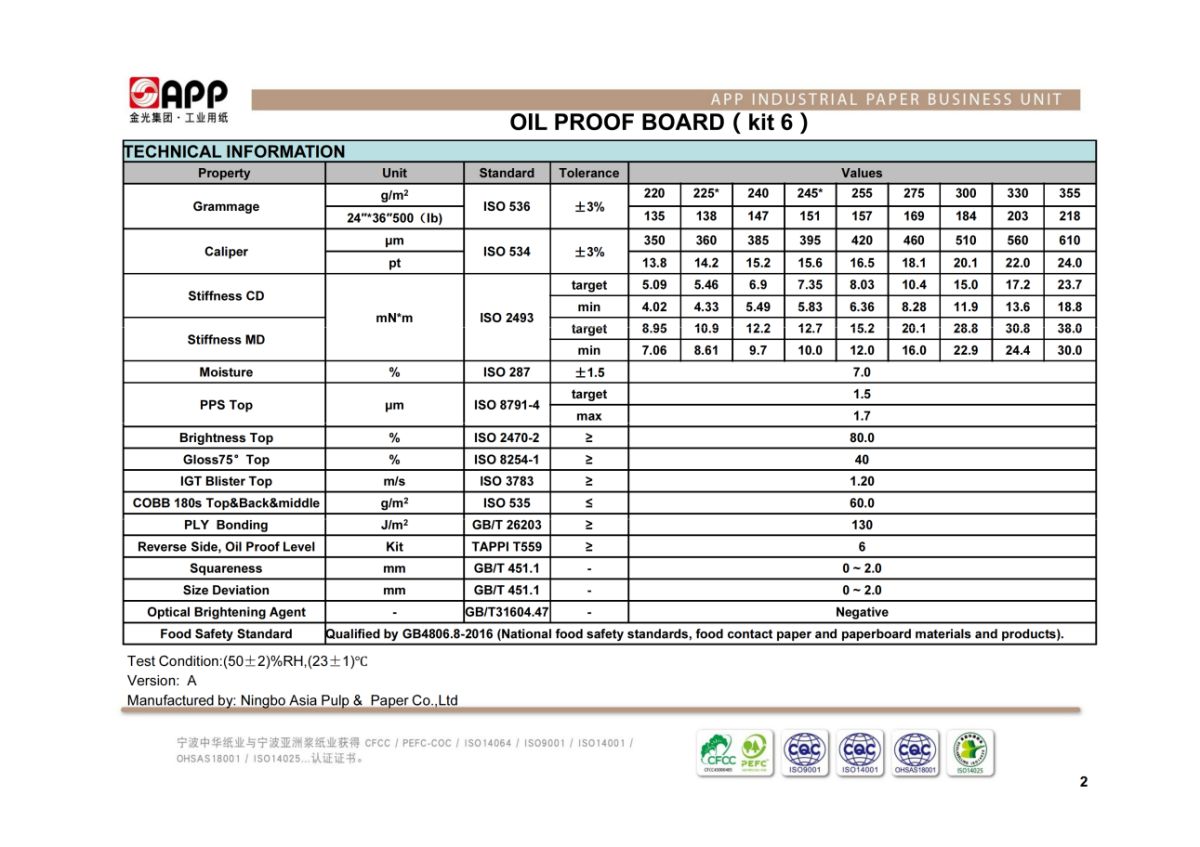

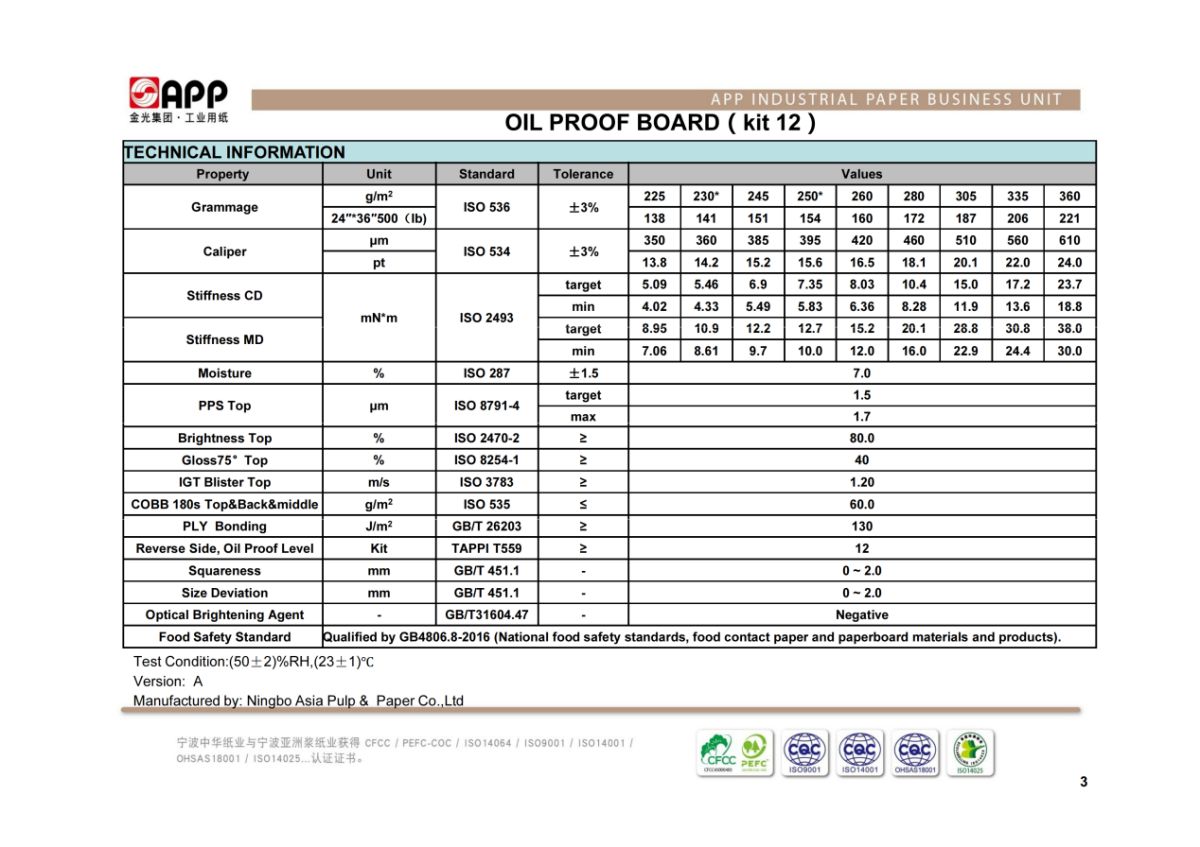

GSM: GCU paper base+5g Kit 6

GSM: GCU paper base+10g Kit 12

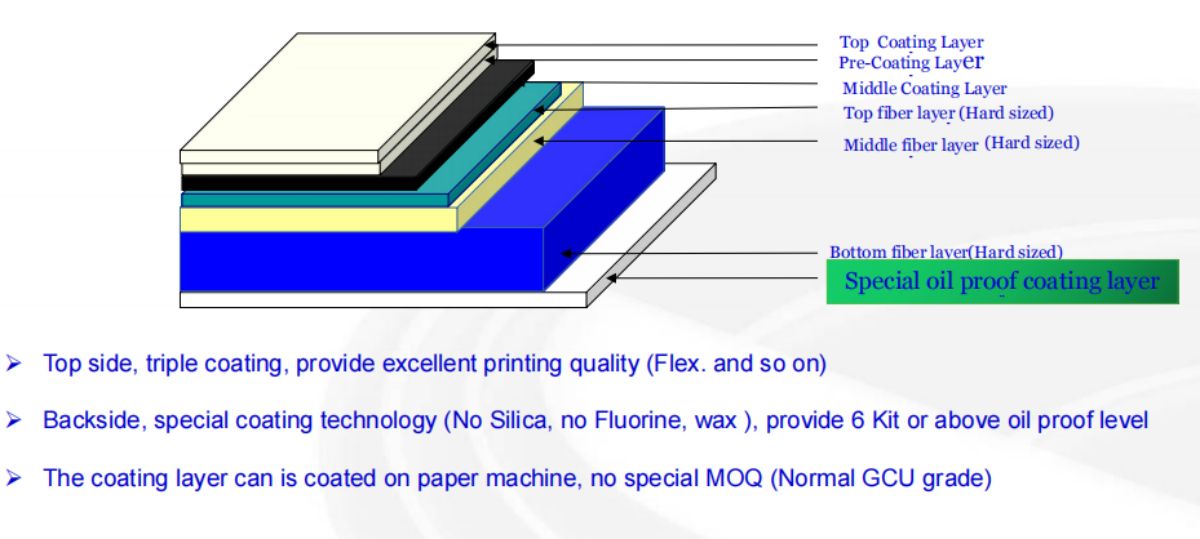

The technology focus an unique coating technology which provide the coated board enough oil resistance, zero odor. OPB also focus three key demand in the market: repulpable (Being recycled in paper or board stream), bio-degradeable, compostble.

Fluoride products like PFOS, PFOA are harmful to the health in despite of its best oil resistance performance, we have to find better solution so as to reduce the overuse in the world. And now more and more governments require to stop using the paper products with Fluoride especially for food contact paper. Fluoride-free Oil repellent agent instead of traditional products.

OPB has below four main advantages:

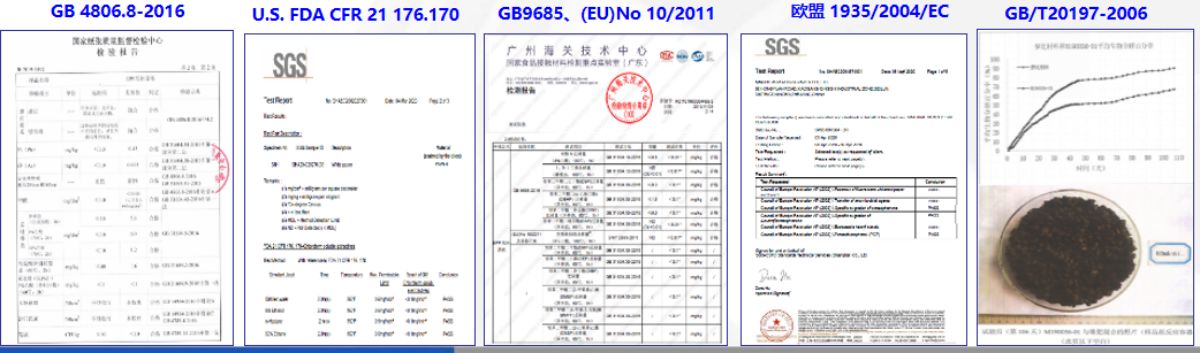

1.Safety: 100% all-wood pulp manufacturing; no silicone oil and fluorine substances; in line with China's national standards (GB4806.8/GB9685) and international certification (FDA, POPs, 1935/2004/EC)

2.Wide range of applications: Wide range of oil-proof, oil-proof grade up to kit 6-12, used for the packaging of containing goods; High temperature resistance, can meet the domestic microwave heating; good water resistance, used for frozen/chilled food packaging and cold chain storage and transportation, as well as various types of food packaging

3.Eco-friendly: Recyclable, using only water-based dispersion coatings, with non-plastic properties, can be recycled without special treatment; degradable, meet GB and EU degradation requirements; non-fluorine and non-silicone, with unique barrier technology.

4.Good post-processing properties: Positive to meet the offset printing, water-based coding and non-water-based coding and other processes; excellent gloss performance, good dot reproduction effect, the finished product color is bright. High looseness and stiffness to meet various packaging processes such as die-cutting, creasing, etc., with good molding performance.

OPB which meet food grade like EC, FDA, GB9685; fluoride-free; plastic-free; silica-free; mineral wax free. It is suitable for the direct production of food packaging cartons, food and beverage grease-proof paper packaging, stamping lunch boxes and so on.

The oil-proof grade is expressed in terms of kit value: the higher the kit value, the better the oil resistance of the cardboard. And compared with pulp molding product, it is low cost and high efficiency. Kit 6: Packaging of French fries, doughnuts and other fried food products Kit 12: Direct packaging of chocolate, ice cream and other products.

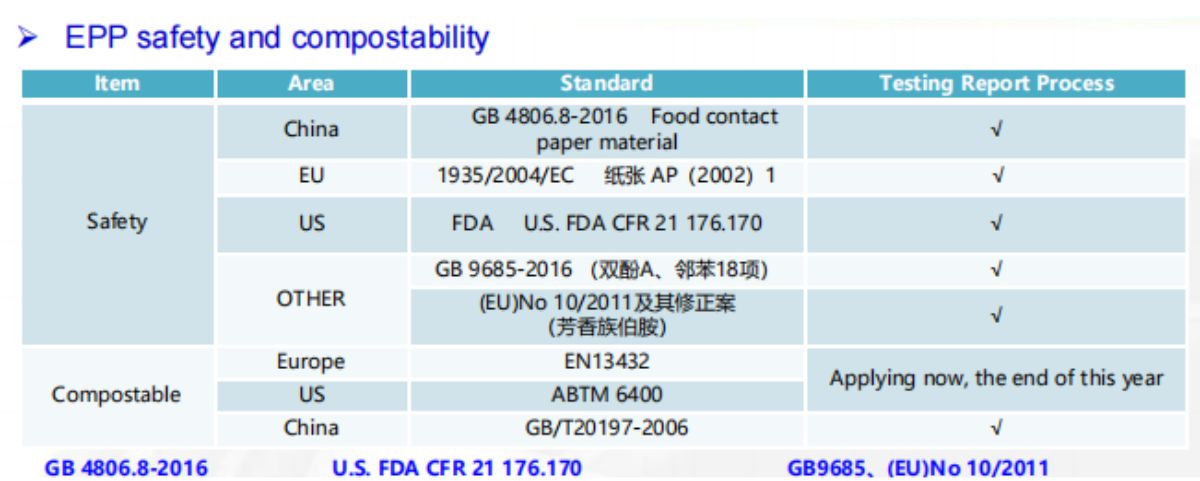

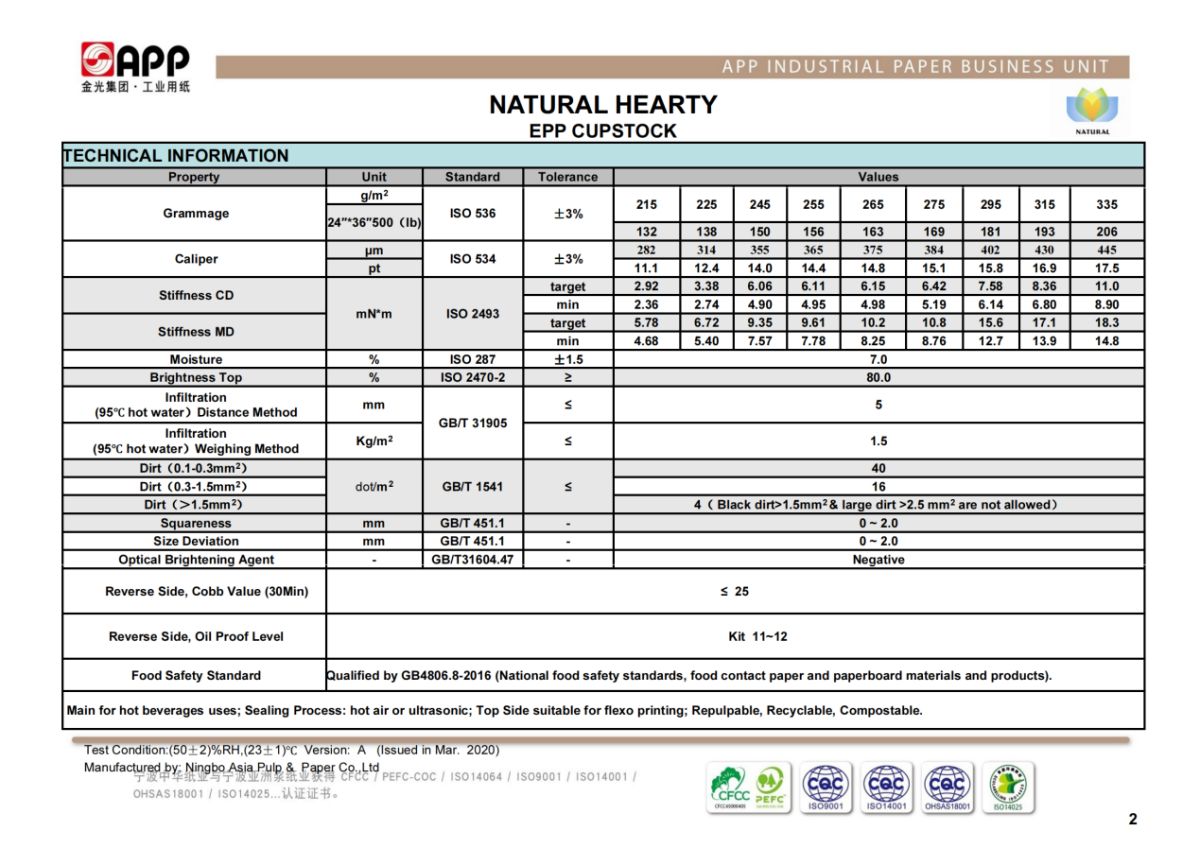

2.APP - EPP

GSM: 200/220/240/270/290/310/330

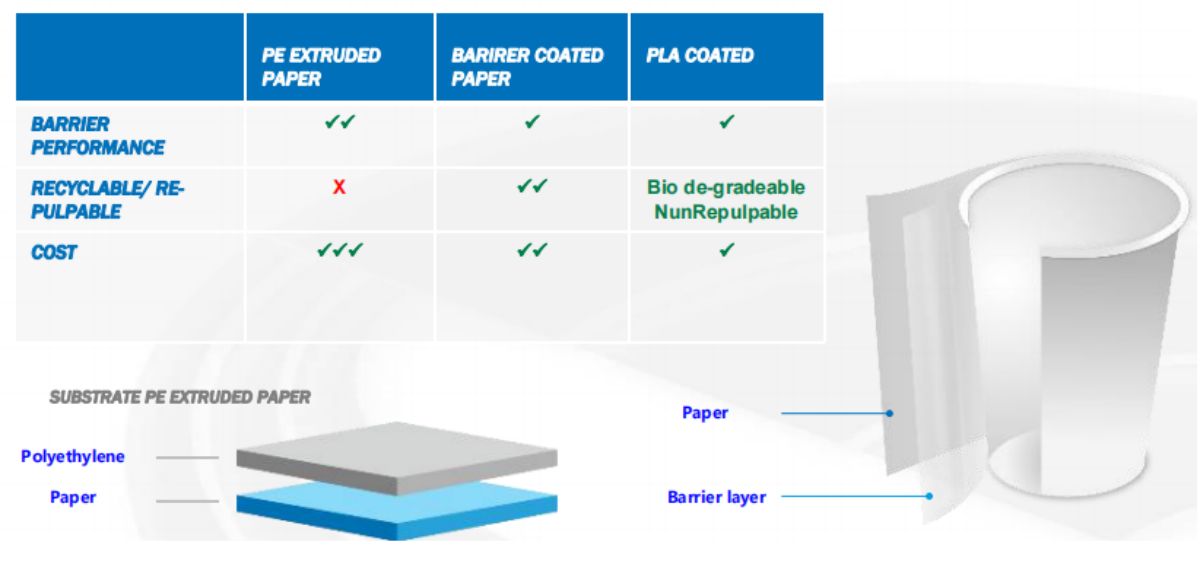

In recent years, the international community has increased its efforts to control, from "Plastic Restriction" to "Plastic Prohibition", and introduced a series of policies or decrees. For the sake of sustainable development, APP China launched EPP which is a special process to create products. EPP is a water-based dispersion coating, which can be processed directly on the paper machine or on top of the coated fabric; it is degradable and recyclable, which is more environmentally friendly than PLA/BIO, which can only be degraded and not recycled.

Compared with the traditional PE lamination paper, the process of zero-plastic paper cup paper EPP is to apply a layer of barrier coating on the original paper, which is used to isolate water and other liquid substances from wetting the original paper, and then apply a layer of heat-sealable coating on top of this so that it can be loaded with all kinds of hot food.

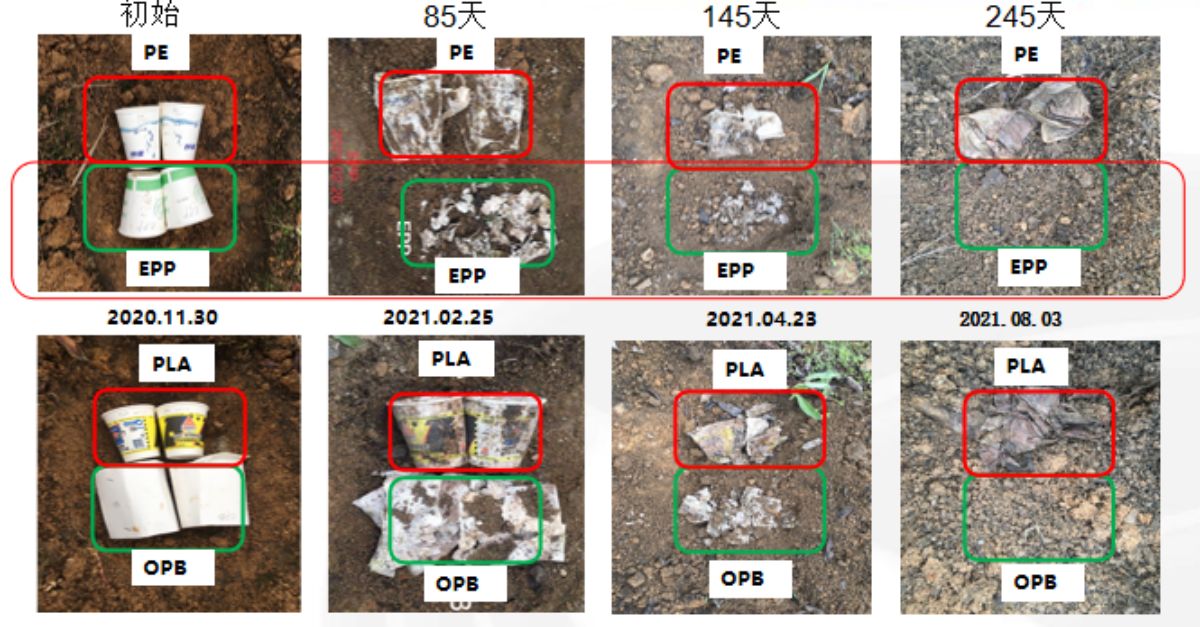

Burying PE/PLA/EPP paper cups and OPB cardboard in the open space. Allowing these to degrade naturally. After each digging of observation, continue to bury these back.

After 245 days, EPP had completely degraded, OPB had a very small amount of debris, PLA fibers were partially susceptible to degradation and membrane fragmentation occurred, and the membrane of PE was essentially intact.

EPP (Environment Protection Polymer) in-line coating, instead of single and double shower, reducing the intermediate link and improving the production efficiency. Its best feature is that the paper comes with waterproof and impermeable properties. It is suitable for directly making all kinds of paper cups, paper bowls, lunch boxes, soup buckets and other take-away catering packaging.

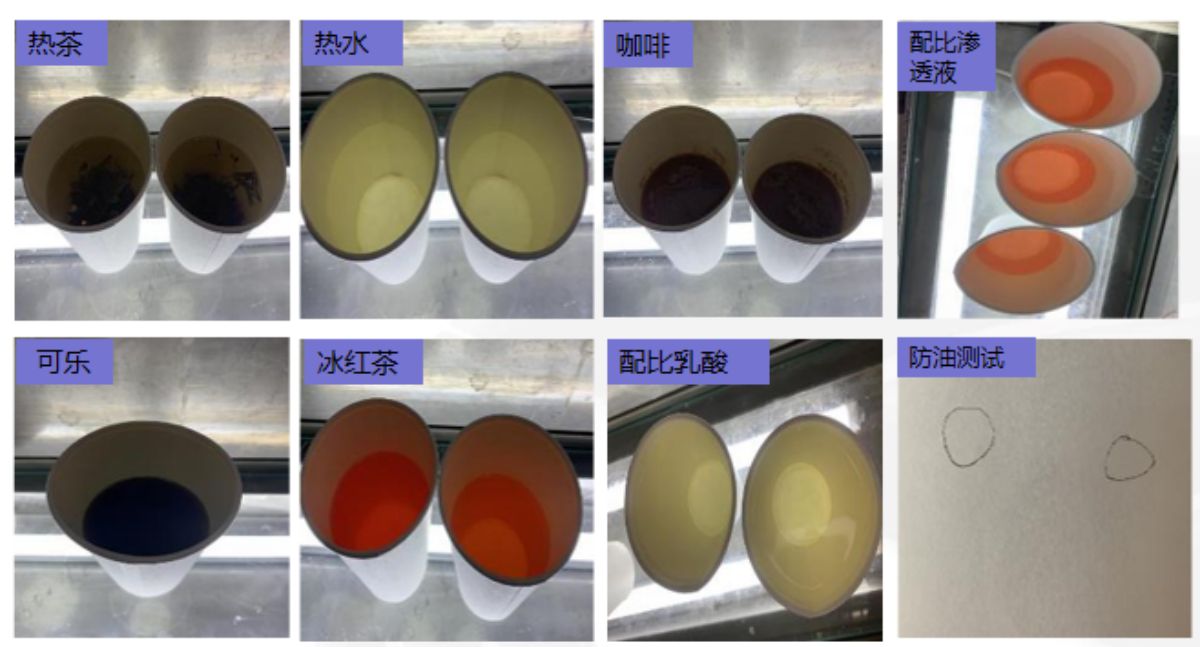

EPP has excellent barrier properties, waterproof, oil-proof, and can be used to make a variety of paper cups, paper bowls, lunch boxes, soup buckets, etc., holding ready-to-eat drinking water, tea, beverages, milk, milk tea, coffee, etc.

EPP can achieve good water and oil resistance and ultrasonic and heat sealing self-adhesive effect without additional coating. Containing coffee, milk tea, drinks and other liquids can reach more than 4 hours without leakage. Does not contain any plastic, completely recyclable, industrial degradation (100%), re-pulping, compostable, safe and environmentally friendly, in line with the development trend of green packaging materials.

EPP zero-plastic coated paper has stronger friction than PE, Ink is easily rubbed and become dirty after printing. So for EPP zero-plastic coated paper we recommend to use flexo printing. In the printing process, special attention need to be paid to ink drying and printing pressure not being too high. It is best to dry under high-temperature and rewind under low-temperature. Besides, the PH value of the ink should be controlled between 8.5-9.5.