INDUSTRIAL IVORY BOARD

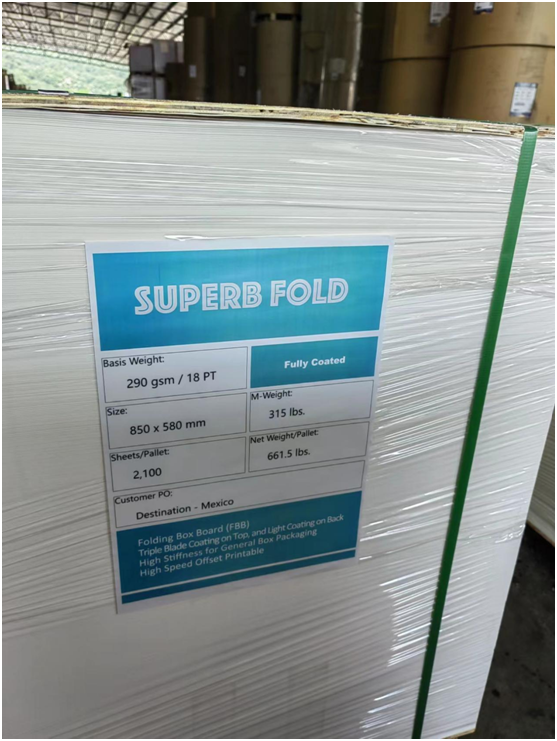

Most of the paper packaging we come into contact with is industrial white cardboard, also known as FBB (FOLDING BOX BOARD), which is a single-layer or multi-layer combined paper that is wholly made of bleached chemical pulp and full-sized. It is suitable for the Printing and packaging of products characterized by high smoothness, good stiffness, clean appearance, and good formation. C1S Ivory board has very high requirements for whiteness. There is A, B, and C three grades according to the different whiteness. The whiteness of grade A is not less than 92%, the whiteness of grade B is not less than 87%, and the whiteness of grade C is not less than 82%.

Due to different paper mills and different usages, FBB is divided into many brands, and ivory board at different prices also correspond to other final products.

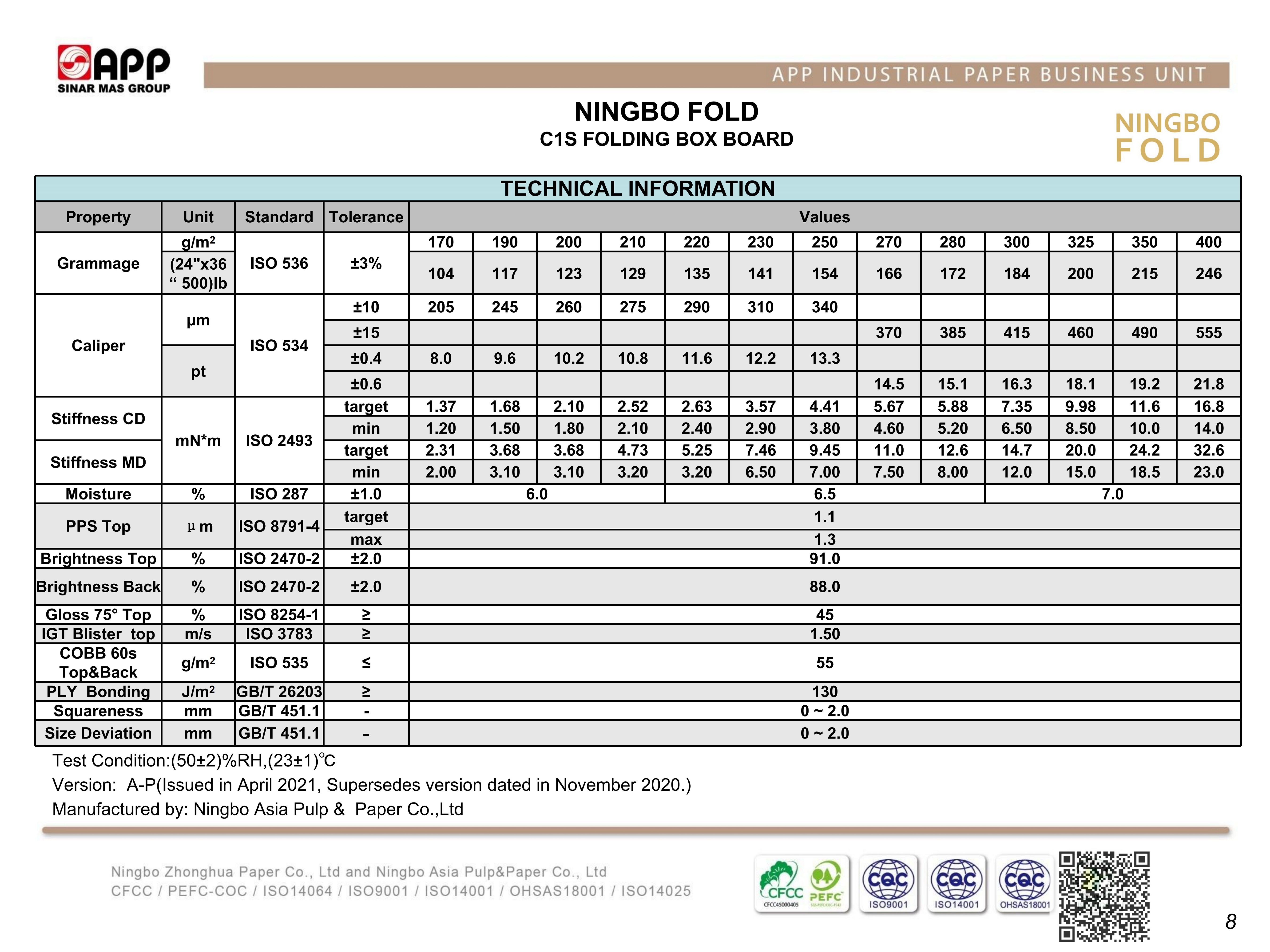

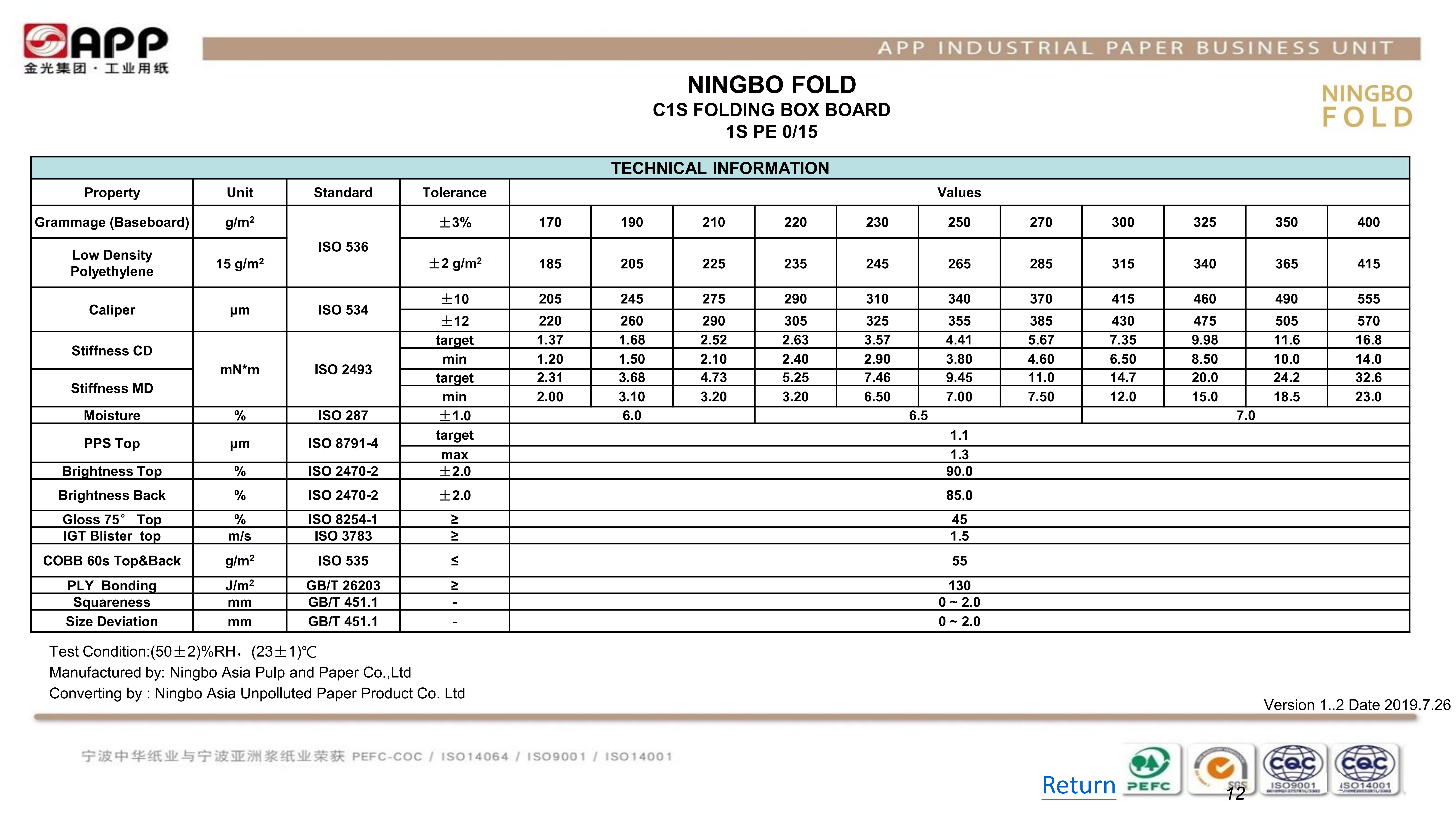

The common packaging on the market is basically made of industrial FBB. Among them, the NINGBO FOLD (FIV) produced by the APP paper mill ( NINGBO ASIA PULP & PAPER CO., LTD ) is the most famous brand, and the others are the IBS, IBC of the BOHUI paper mill. (Now BOHUI PAPER MILL also belongs to the APP group, getting better managed and more stable production every month )

The regular GSM of NINGBO FOLD (FIV) is 230gsm, 250gsm, 270gsm, 300gsm, 350gsm, 400gsm.(same price for range 230-400 GSM )

FOOD GRADE BOARD

Due to the whiteness requirements of industrial FBB, fluorescent whitening agents are added, but this additive is harmful to the human body, so the food-grade board is not allowed to add fluorescent whitening agents. The card is the same as industrial FBB, but it has higher requirements on the workshop environment and the composition of the paper, and cannot contain substances that are harmful to the human body.

Since it does not contain fluorescent whitening agents, the food-grade board is basically yellowish in color and is mainly used in food-related packaging or high-end cosmetic maternal and child products.

Food-grade board can be divided into the ordinary food-grade board which can be used for frozen products.

NORMAL FOOD-GRADE BOARD

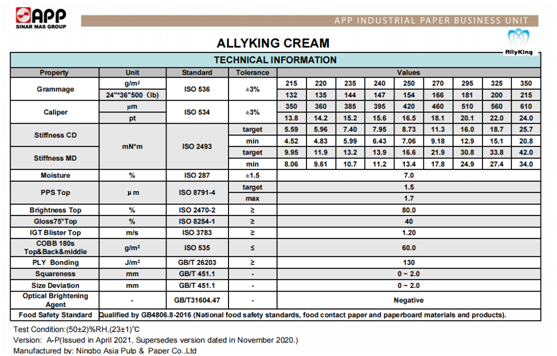

FVO is a high bulk food-grade board and has passed QS certification. It is made of wood pulp, without a fluorescent whitening agent, with good stiffness and uniform thickness. The surface is delicate, the printing adaptability is strong, the printing gloss is excellent, the printing dot restoration effect is good, and the printed product is colorful. Good post-processing adaptability, satisfying various packaging processes such as lamination and indentation, good molding, and no deformation. Exceptional paper for lightweight food packaging, which can be used for the packaging of maternal and infant skin care products, feminine products, personal hygiene products, solid food packaging (milk powder, cereals), and other products.

The regular gsm of FVO is 215gsm, 235gsm, 250gsm, 275gsm, 295gsm, 325gsm, 365gsm.

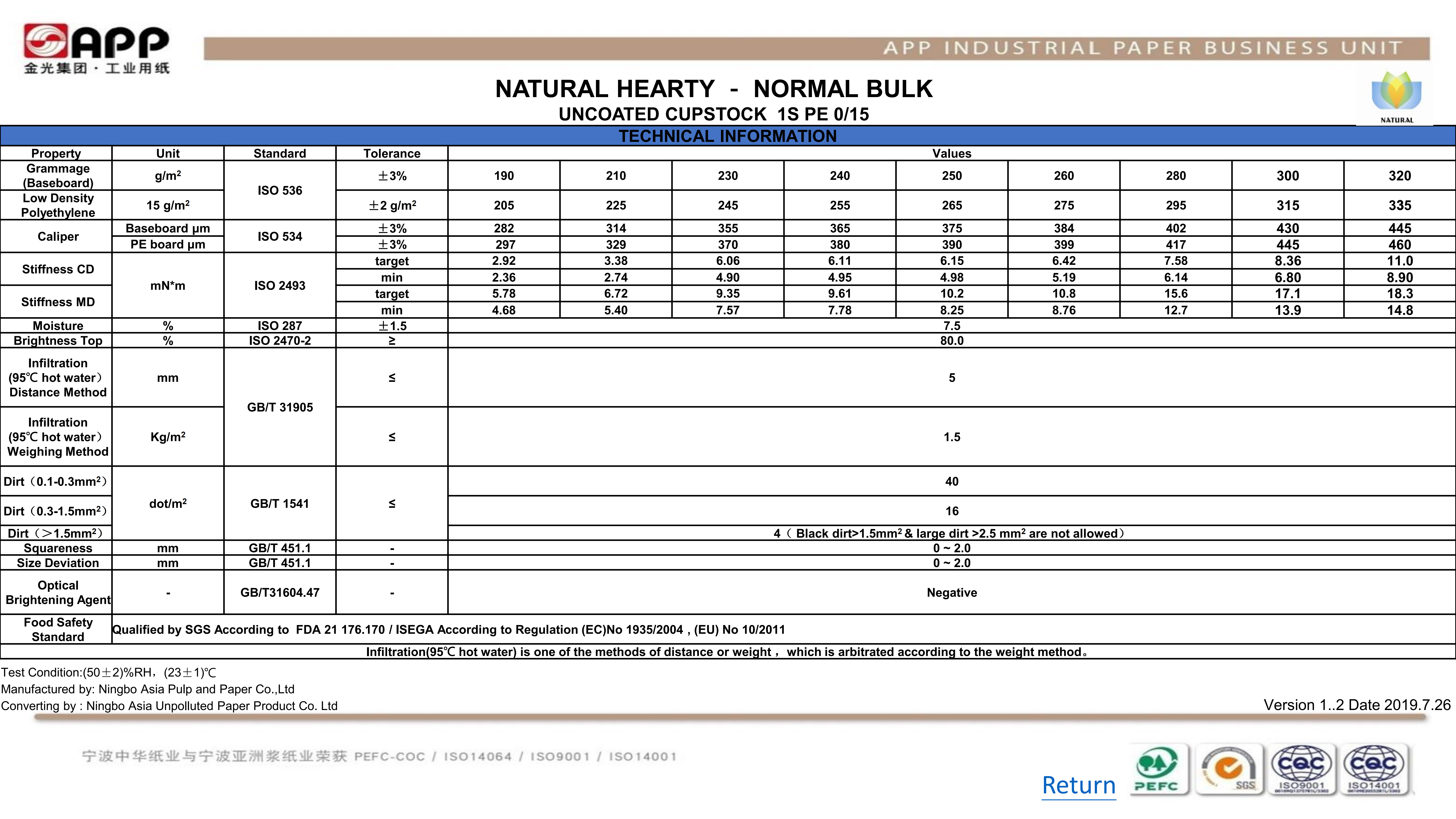

It is a food-grade board specially used for making disposable tableware such as paper cups, paper bowls, etc.

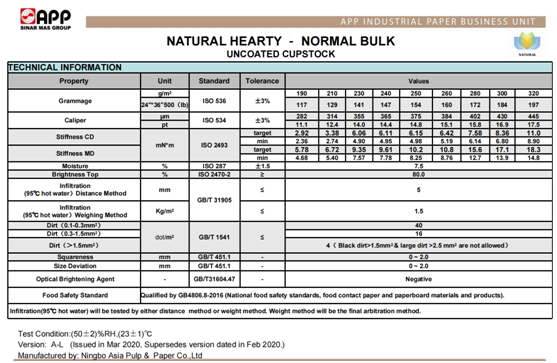

FK1 (NATURAL HEARTY -Normal bulk )

It is passed QS certification, all wood pulp papermaking, with no fluorescent whitening agent, good stiffness, no peculiar smell, excellent resistance to hot water edge penetration; uniform thickness, fine paper surface, good surface flatness, and good printing adaptability. The post-processing adaptability is good, and it can meet the processing technology of laminating, die-cutting, ultrasonic, thermal bonding, etc., and has a good molding effect. Special paper for paper cups, a good combination of the paper surface and PE, suitable for single & double-sided lamination. The cups (hot cups) made of PE coated on one side are used to hold ready-to-eat drinking water, tea, beverages, milk, etc.; the cups (cold cups) made of double-sidedlaminated films are used to hold cold drinks, ice cream, etc.

We can accept customized orders from different customers, which can be in the reel of raw material ( NO PE) or sheet (NO PE ), PE coated in roll or sheet ( bulk pack ), or printed and after die-cut.

The regular gsm is: 190gsm, 210gsm, 230gsm, 240gsm, 250gsm, 260gsm, 280gsm, 300gsm, 320gsm.

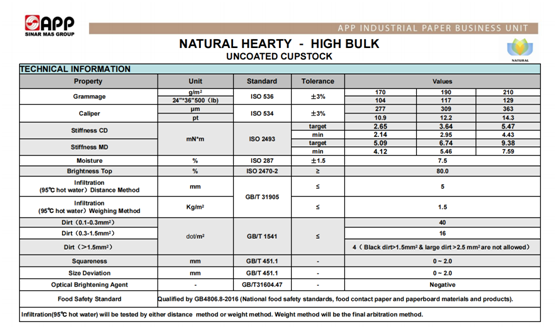

FK0 (NATURAL HEARTY -High bulk )

The same as FK1 but with high bulk.

The regular gsm is: 170gsm, 190gsm, 210gsm.

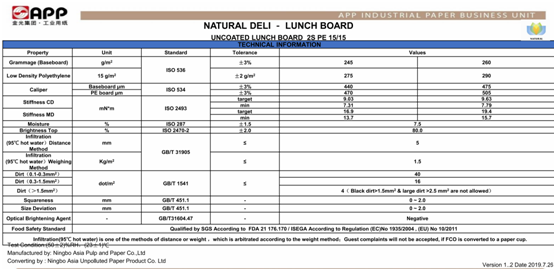

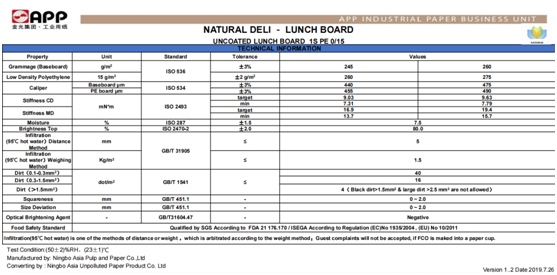

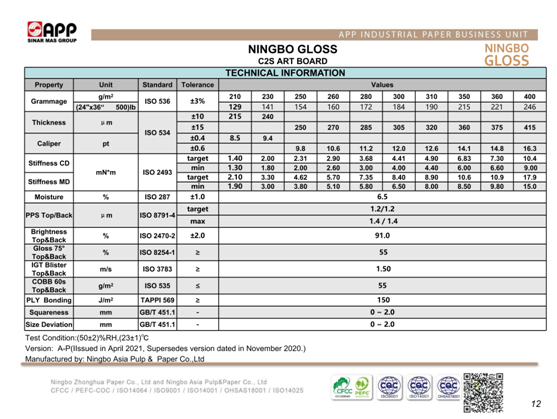

FCO

Passed QS certification, all wood pulp paper making, no fluorescent whitening agent, fully in line with national food safety requirements. Uncoated, uniform thickness, ultra-high bulk, high stiffness, high folding resistance, no peculiar smell, strong adhesion between layers, not easy to delaminate. Good surface flatness, good printing adaptability, good post-processing adaptability, meet the processing technology of laminating, die-cutting, ultrasonic, thermal bonding, etc., with good molding effect, indentation folding does not burst, not easy to deform. Special paper for lunch boxes, suitable for making all kinds of high-end lunch boxes.

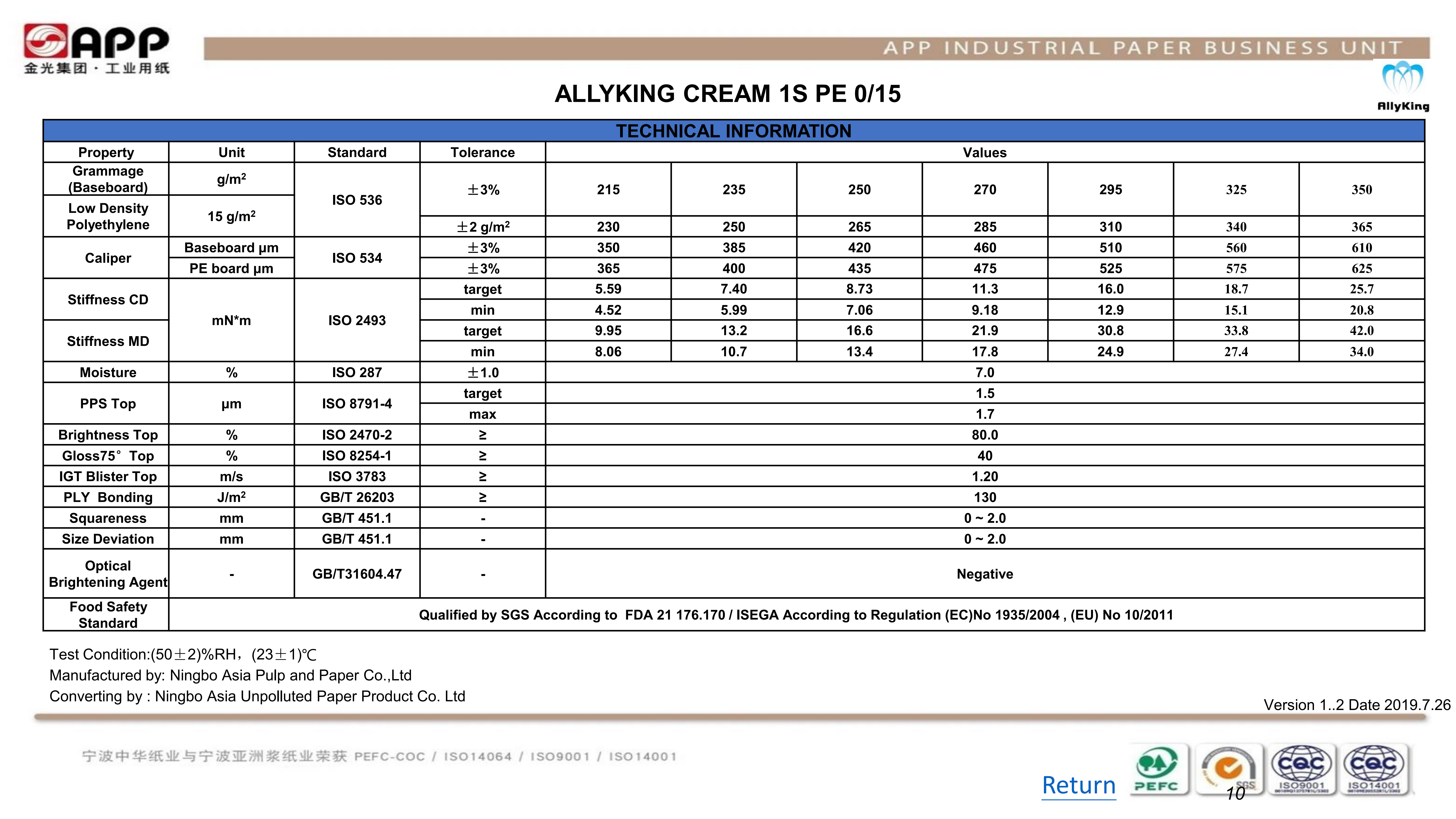

And our end users usually will add PE coating on it , 1 SIDE or 2 SIDE PE ( paper TDS attached as below )

The regular gsm:245gsm,260gsm.

DUPLEX BOARD

The duple board is also a very widely used paper in the packaging industry. In addition to the ivory board, common packaging materials also includes duplex board. Duplex board is a kind of uniform fiber structure, with filler and sizing components on the surface layer and a layer of paint on the surface, which is produced by multi-roller calendering. This kind of paper has high color purity, relatively uniform ink absorption, and good folding resistance, and the duplex board has small flexibility, and toughness, and is not easy to break when folded. It is mainly used for printing packaging boxes. Duplex board can be divided into white back duplex board and grey back duplex board.

The duplex with a white back is double-sided white, the regular gsm is 250/300/350/400/450gsm.

The duplex with a grey back is one side white and one side grey, it is normally cheaper than a double-sided white duplex, and the regular gsm varies from different brands.

LIAN SHENG GREEN LEAF:200/220/240/270/290/340gsm.

LIAN SHENG BLUE LEAF:230/250/270/300/350/400/450gsm.

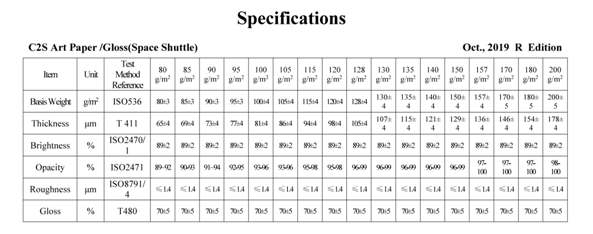

C2S ART PAPER/BOARD

Coated paper and coated board are often used in printing, so what is the difference between coated paper and coated board? Generally speaking, coated paper is lighter and thinner. In terms of usage, the two are also different.

Coated paper, also known as coated printing paper, is called powdered paper in Hong Kong and other regions. It is a high-grade printing paper made of base paper coated with white paint. It is mainly used for printing the covers and illustrations of high-end books and periodicals, color pictures, various exquisite commodity advertisements, samples, commodity packaging, trademarks, etc.

The characteristic of coated paper is that the paper surface is high in smoothness and has good gloss. Because the whiteness of the paint used is more than 90%, the particles are extremely fine, and it has been calendered by a super calender, the smoothness of the coated paper is generally 600~1000s.

At the same time, the paint is evenly distributed on the paper and shows a pleasing white color. The requirement for coated paper is that the coating is thin and uniform, without air bubbles, and the amount of adhesive in the coating is appropriate to prevent the paper from powdering and hair loss during the printing process.

The following is the detailed difference between coated paper and coated card:

Characteristics of coated paper:

1. Forming method: one time forming

2. Material: high quality raw material

3. Thickness: general

4. Paper surface: delicate

5. Dimensional stability: good

6. Strength/Stiffness: Normal, Internal Bonding: Good

7. Main application: picture book

The regular gsm of art paper: 80gsm, 90gsm, 100gsm, 128gsm, 158gsm, 200gsm, 250gsm, 300gsm.( It means for gsm from 80-300 gsm art paper can be in glossy or matte )

Characteristics of coated board:

1. Forming method: one-time molding and multiple molding together, generally three layers

2. Material: cheap fiber can be used in the middle

3. Thickness: Thick

4. Paper surface: slightly rough

5. Dimensional stability: slightly worse

6. Strength/Stiffness: Strong, Internal Bonding: slightly worse

7. Main application: package

The regular gsm of C2S art board: 210gsm, 230gsm, 250gsm, 260gsm , 280gsm, 300gsm, 310gsm, 350gsm, 360gsm, 400gsm. ( Art board over 300 gsm can only in gloss, no matte )

OFFSET PAPER

Offset paper, formerly known as "Daolin paper" and wood-free paper is mainly used for lithographic (offset) printing presses or other printing presses to print higher-level color prints, suitable for printing single-color or multi-color book covers, texts, inserts, pictorials, maps, posters, color trademarks, and various packaging paper.

Offset paper is generally made of bleached coniferous wood chemical pulp and an appropriate amount of bamboo pulp.

When processing offset paper, filling and sizing are heavy, and some high-grade offset papers also need surface sizing and calendering. Offset paper uses the principle of water-ink balance when printing, so the paper needs to have good water resistance, dimensional stability and strength. Offset paper has the advantages of white quality, crispness, flatness and fineness. After the books and periodicals are made, the characters are clear, and the books and periodicals are flat and not easy to deform.

Offset paper can be classified according to color: super white, natural white, cream, yellow.

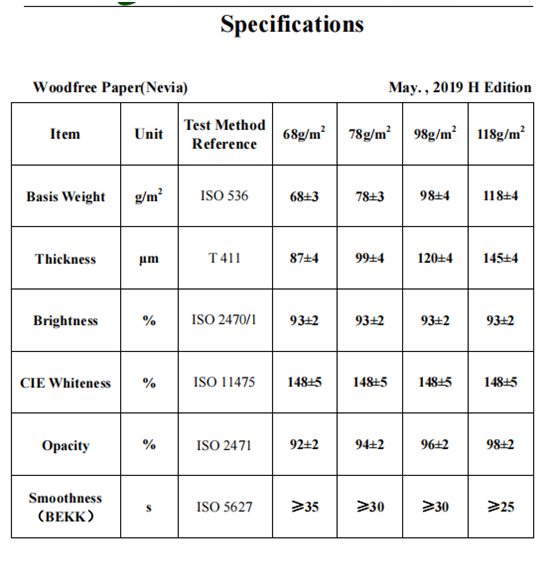

The regular gsm of offset paper: 68gsm, 78gsm, 98gsm, 118gsm.