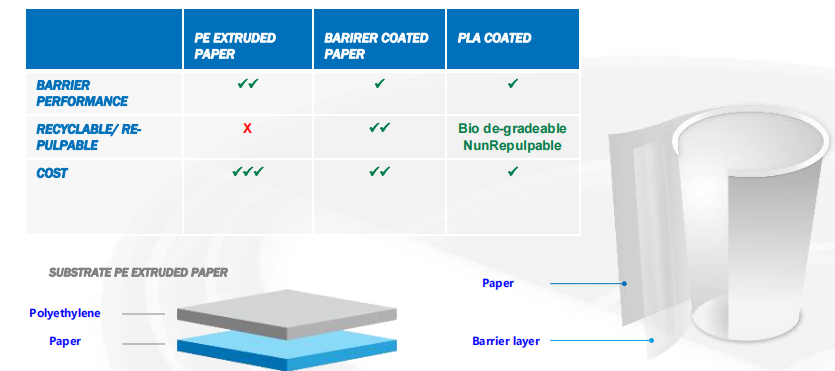

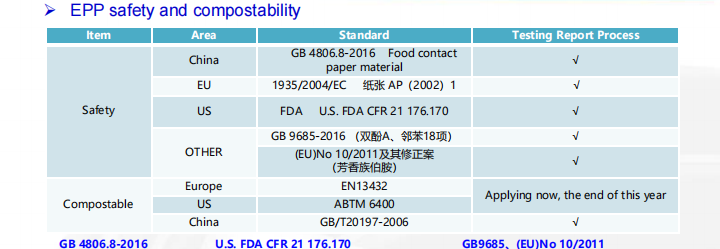

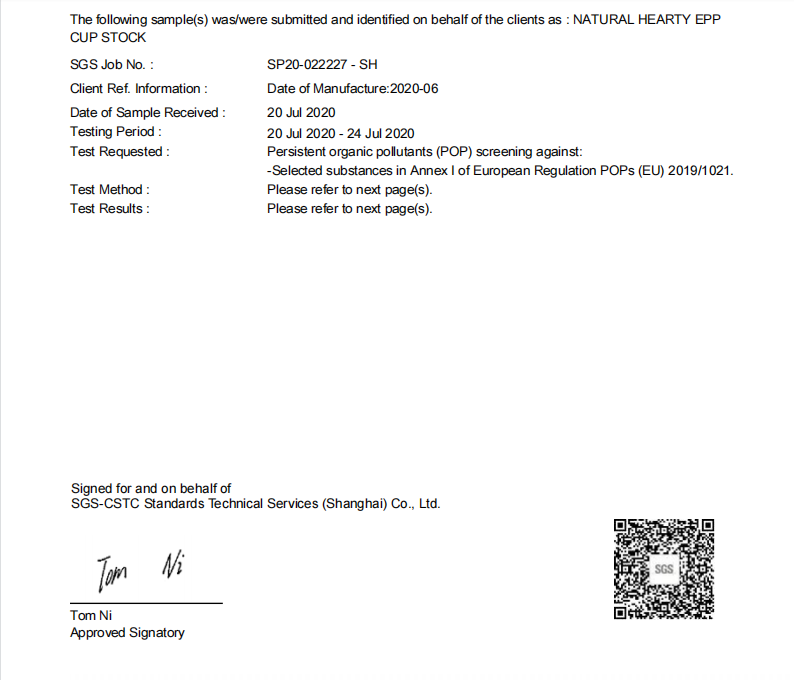

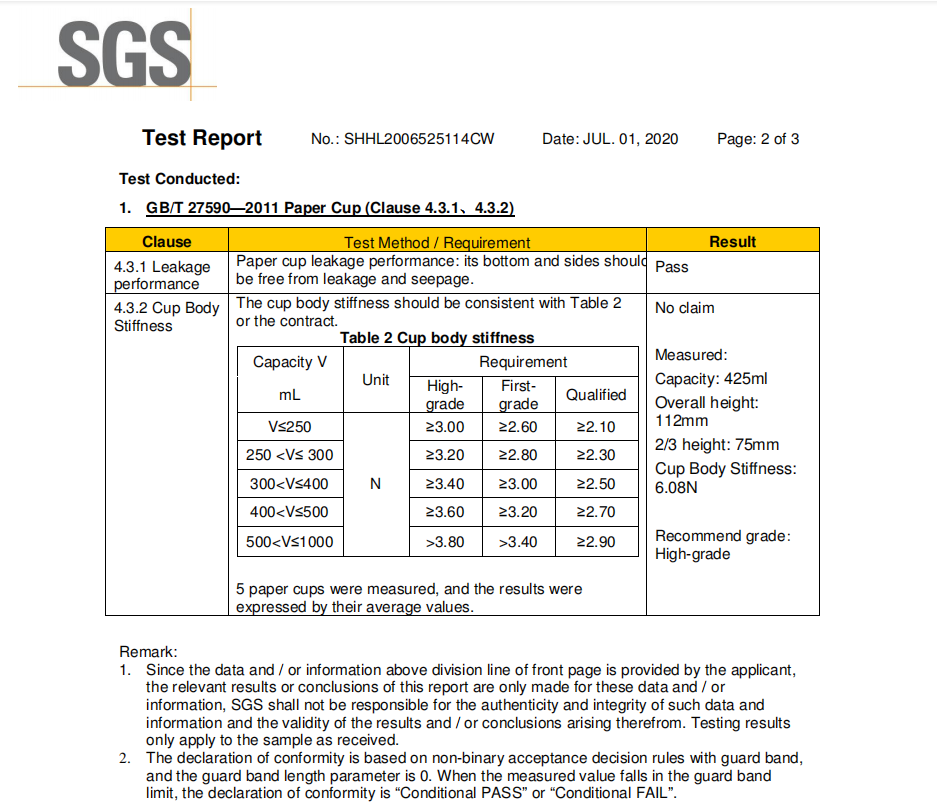

new design From APP friendly cupstock (EPP coated)Food Grade Bio de-gradable paper

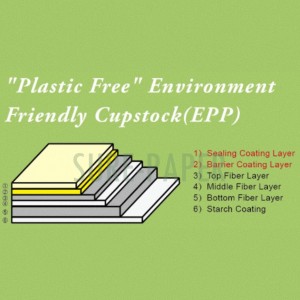

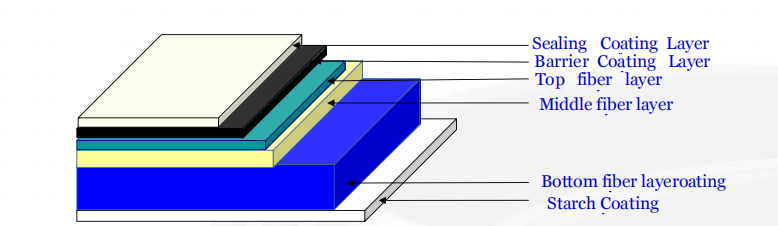

1)EPP is three English Words's Abbreviation: Environment Protection Polymer, it is the code of our new product (Zero plastic or plastic free cupstock ), like GCU,also a patened technology which we developed in NAPPEPP

2)The technology focus an unique coating technology which provide the finished cup excellent hot sealing performance,water or oil resistance, low migration (to beverage), low odor

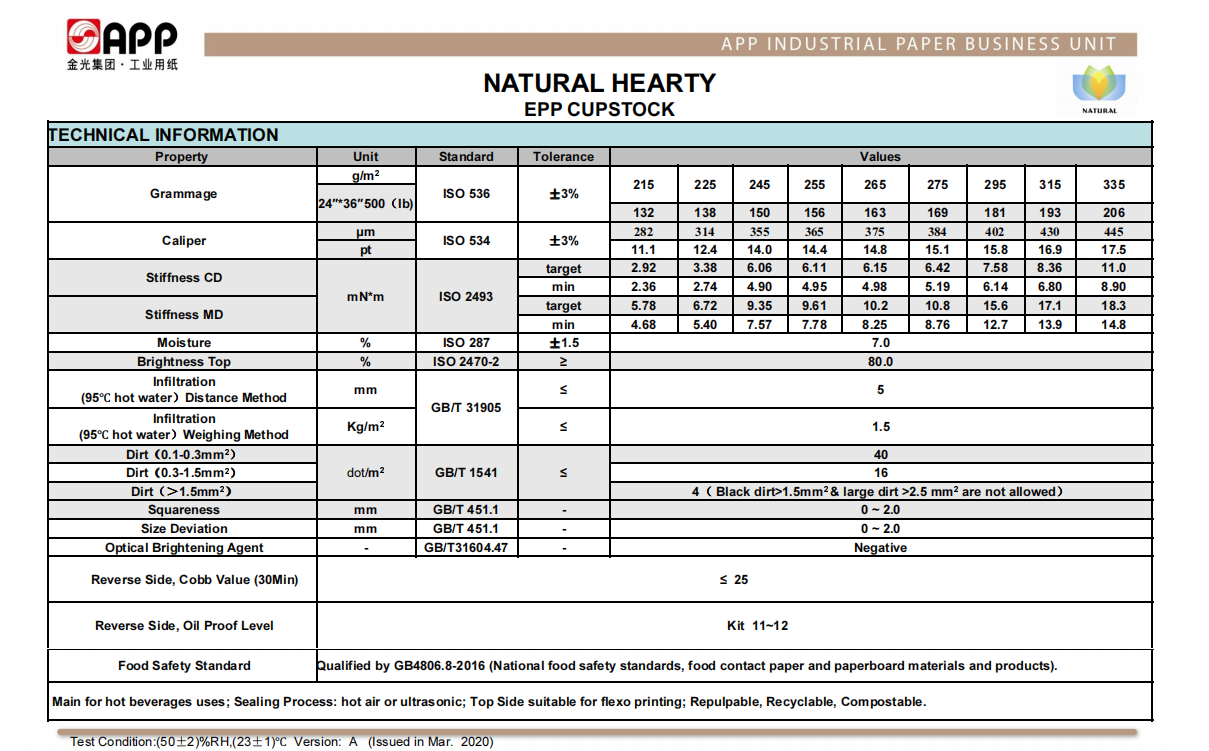

3)Our EPP also focus three key demand in the market: repulpable (Beingrecycled in paper or board stream), bio-degradable, Compostable

1)The plastic is everywhere!

2)To being a member of the Earth, everyone has the responsibility to do something

3)To being a papermaker, we should do sth., we have the capability to do something

4)To being the largest pulp and paper enterprise in the world, we should do something

1)Our main challenge is to reduce and eliminate non-reworkable packaging waste.

2)Our mission is to create materials that enable sustainable packaging solutions for

our daily lives.

√ LDPE global production ca. 25million ton

- China: 3.5million, 14.5%

- USA: 13.3%

- Japan: 5.2%

√ Top3 manufacturers:

- Exxon Mobile: 1.6million, 6.5%

- Lyondell Basel: 1.55million, 6.3%

- Sinopec: 1.47million, 6%

√ China demand ca. 5.5million/a

√ Global Paper Cup LDPE demand ca.

0.7 million/a, CN about 0.2m/a

1)For packaging applications, our sustainable EPP coating technologies are a healthy solution for the entire value chain, and unique appearance and performance.

2)Create bespoke textures to match your brand identity

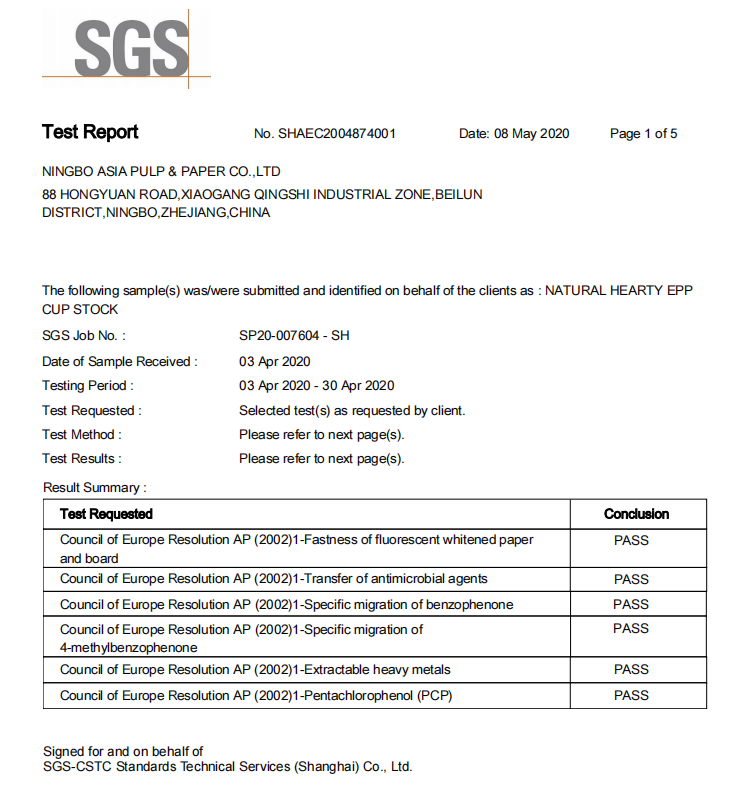

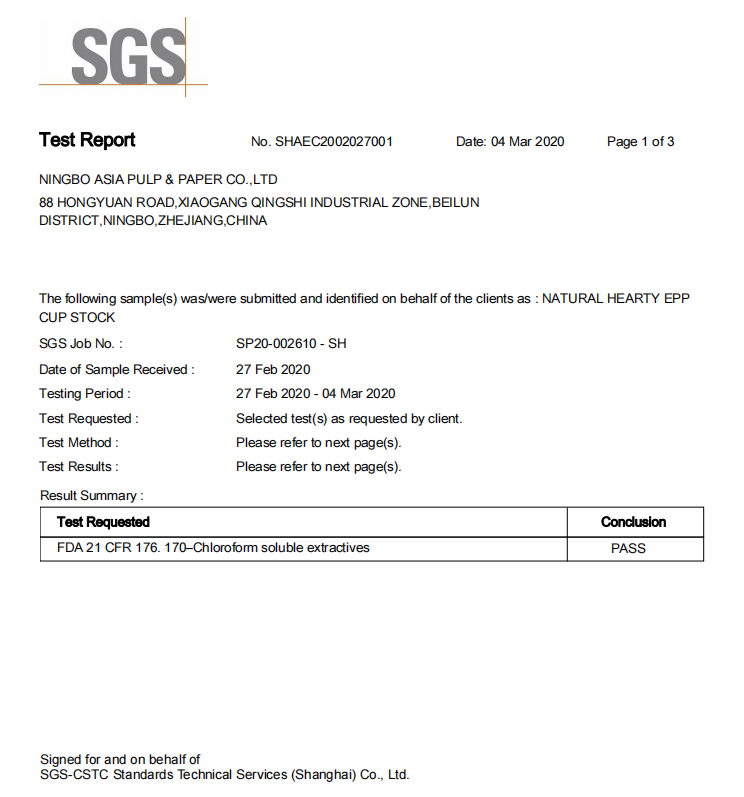

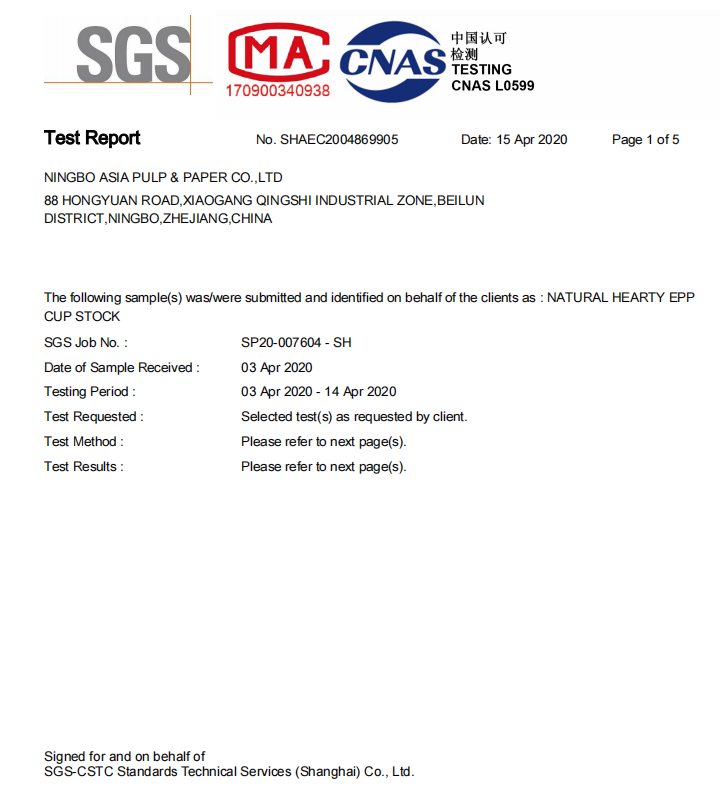

3)Packaging compliant with food contact regulations

4) Products which fulfill barrier coating requirements

Office

Warehouse

Our Workshop

Produce

Our Service

Welcome to SURE PAPER, where over a decade of unparalleled expertise in the paper industry and international trade meet to provide you with the gold standard in quality and service. We are more than a supplier; we are your strategic ally, committed to propelling your success through our distinct advantages.

**Professionalism at Every Level**

Our team's ten-plus years in the paper sector give us an edge in staying ahead of market trends, ensuring that you receive timely insights to keep your business one step ahead. By maintaining strong relationships with top-tier paper mills such as "APP," "CHENMING," “BOHUI”, "IP SUN," ect .We pledge superior quality and reliable after-sales support within three months of cargo arrival. With every product, we include a certificate of conformity that details specifications like weight, rewinding direction, and outgoing codes, fostering transparency and trust with every transaction.

**Competitive Pricing with Confidence**

As a favored agent, we pass on the benefits of our substantial purchasing power—over 3000 tons per month—directly to you. Our ability to buy in bulk allows us to secure advantageous prices, which we are pleased to offer to our clients, ensuring that you receive the best deal without sacrificing quality.

**Swift and Tailored Order Fulfillment**

We understand the critical nature of time. With a robust inventory ( for our domestic market sales )that boasts over 3000 tons each month, we can promptly fulfill your diverse paper requirements. Our deep collaboration with mills enables us to arrange priority shipments for your urgent orders, helping you maintain pace with your fast-moving schedule.

**A One-Stop Shop for All Your Paper Needs**

From coating to PE lamination, printing, cutting, and packaging, SURE PAPER offers an all-encompassing suite of services designed to streamline your operations. As your sole point of contact for all things paper-related, we simplify your processes, freeing up your time to focus on what truly matters to your business.

**Superior Quality That Outperforms Local Markets**

At SURE PAPER, we're dedicated to helping you achieve more with less. By offering competitive prices that match or exceed the quality of papers in your local market, we enable you to work smarter, leaving the heavy lifting to us. A small investment of your time is all it takes to manage a significant portion of your paper needs – setting you free to concentrate on other key areas of your business.

**Immediate Access to Samples**

We make it easy. Multiple samples are available at no charge, and if in stock, they can be sent out the same day, empowering you to make quick, informed decisions with confidence.

At SURE PAPER, our mission goes beyond selling paper—we aim to build thriving relationships founded on quality, trust, and added value. Partner with us to transform your paper supply chain. Contact us today to discover how we can turn your paper procurement into an efficient and rewarding experience.